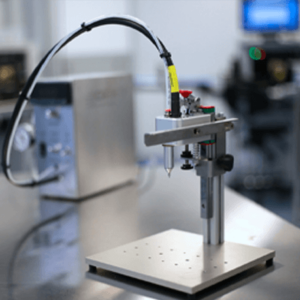

Flex-Drill by CATHTIP is the most flexible, cost-effective option for hole forming in catheter prototypes and early development applications. The drill can be mounted or handheld and operated by a foot pedal making it quick and easy to try new hole diameters or patterns in a variety of different tubing materials. The Flex-Drill utilizes the superior Flow Thru™ bit technology found in CATHTIP’s hole forming machines allowing for easy core evacuation and a clean workstation.

Flex-Drill by CATHTIP is the most flexible, cost-effective option for hole forming in catheter prototypes and early development applications. The drill can be mounted or handheld and operated by a foot pedal making it quick and easy to try new hole diameters or patterns in a variety of different tubing materials. The Flex-Drill utilizes the superior Flow Thru™ bit technology found in CATHTIP’s hole forming machines allowing for easy core evacuation and a clean workstation.

- Mountable in drill press with motion platform

- Quick removal from stand with toggle clamp

- Fine tune depth stop

- Reference ruler on the side

- Quiet operation (enclosed vacuum generator)

- Several mounting hole options for tooling

- T-Slot mountable

- Control via foot pedal or robot

- Open source tooling design platform

- Motion: Nema 17 Stepper motor

- Power: 120V at 50/60Hz

- Air: 100psi max. 5cfm

- Dimensions: 8” x 11”x 11” [from tabletop]

- Weight: 15lb

- Over two dozen drill bit sizes from 0.015 “-0.197”

- Panel dial set speed from 100-2000RPM

- Collet-style drill head for punches & ejector pin (optional)