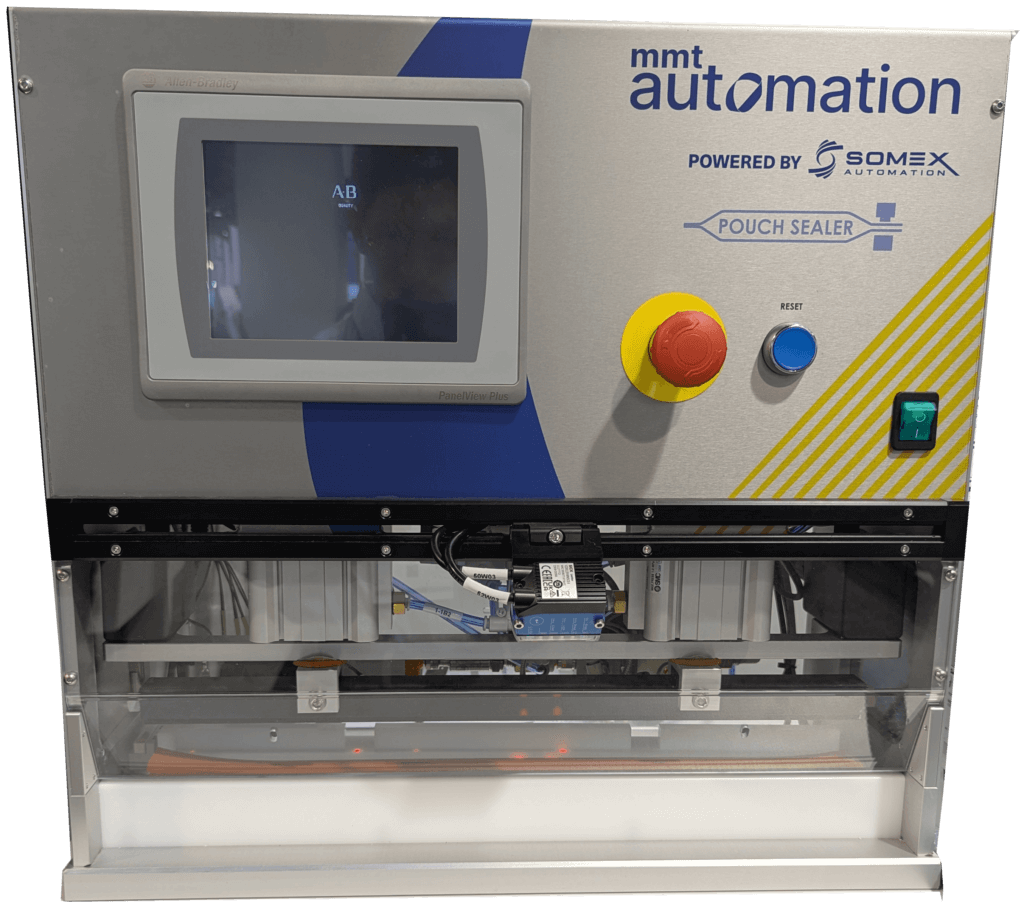

The New Generation Bar Pouch Sealer (Model#: BPS-010) is a compact tabletop Bar Sealer, PLC controlled and interfaced with a label printer to control (poka-yoke) your pouch labeling and sealing process. It incorporates the new upgraded control system.

Key Features

- Accurate digital control of temperature, pressure, and time.

- Includes an Allen Bradley PLC programmed with standard functions for Barcode & printer integration functionality to poka-yoke the sequence of the sealing and printing process to mitigate against the occurrence of un-labeled and un-sealed pouches leaving the sealing station.

- Touch screen Allen Bradley 7” HMI. Key features include:

- Recipe-based product/parameter selection through barcode scanner or from HMI.

- Display/monitoring of the process parameters, (temperature, pressure & time) and process alarm messages.

- Calibration screen to simplify the calibration process.

- 450 mm sealer bar with 10mm seal width. Other widths can available upon request.

- Sealer tooling defines the sealing position of the pouch and verifies the correct pouch size for the UPN.

- CE Compliant.

The upgraded design Bar Pouch Sealer Machine is designed using state-of-the-art technology.