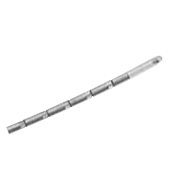

Challenge: To size implantable spinal cord stimulation devices that deliver precise doses of electricity to targeted nerve sites for patients suffering from chronic back problems. The device is long and flexible, which made it difficult to handle. It is also constructed of dissimilar materials of varying diameters, from metal conductive rings to fine electrical micro-wires to molded polymer and plastic supports, which made grinding a fine surface finish with stringent diameter control and without damage to the parts very challenging.

Solution

The TF-9DHD infeed grinding machine with granite base provides the stability needed to grind long, flexible parts. The configuration of the integrated 8-5/8” grinding wheel with pressure washing system allowed us to grind both the polyurethane material and the metal rings in one operation, without damaging the delicate wire connections, removing 0.150”. Additionally, the CE enclosure contained coolant, allowing the machine to operate in a clean room.