Current Process

The melamine fuse bodies are ground using a legacy hydraulically operated centerless form grinder. Decades of use have prompted customers to replace existing machines with newer versions.

Challenges

Simplify the setup process and create a consistent operation. Ensure that the OD dimensions of the melamine fuse bodies are uniform and within the allowed tolerance.

Solution

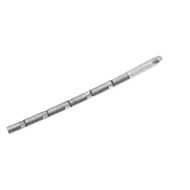

PG-9DHD Centerless Form Grinder

The PG-9DHD is equipped with an intuitive HMI that facilitates and standardizes the setup procedure. The infeed motion is executed using a servo motor for better tolerance and control. During testing, this PG-9DHD operated with a 17 second cycle time while maintaining the required tolerances of +/- 0.05”-0.2”.

The PG-9DHD Centerless Form Grinder is available with remote connectivity, gauging, automation interfacing, and precise positioning.

As demand for electric vehicles increases, fuse bodies are in higher demand requiring greater manufacturing efficiencies to meet production needs and reduce costs.

Depending on the part, this centerless form grinder can cut each 10” fuse body tube into 2, 3, or 4 pieces, reducing the grinding process to one step with no operator intervention and minimal maintenance.