Single Head Laminator

MMT’s Somex Automation Single Head Laminator is a compact versatile tabletop Hot Air Nozzle Horizontal Laminator System. It features digital control of airflow, a ready lamp for temperature & airflow, […]

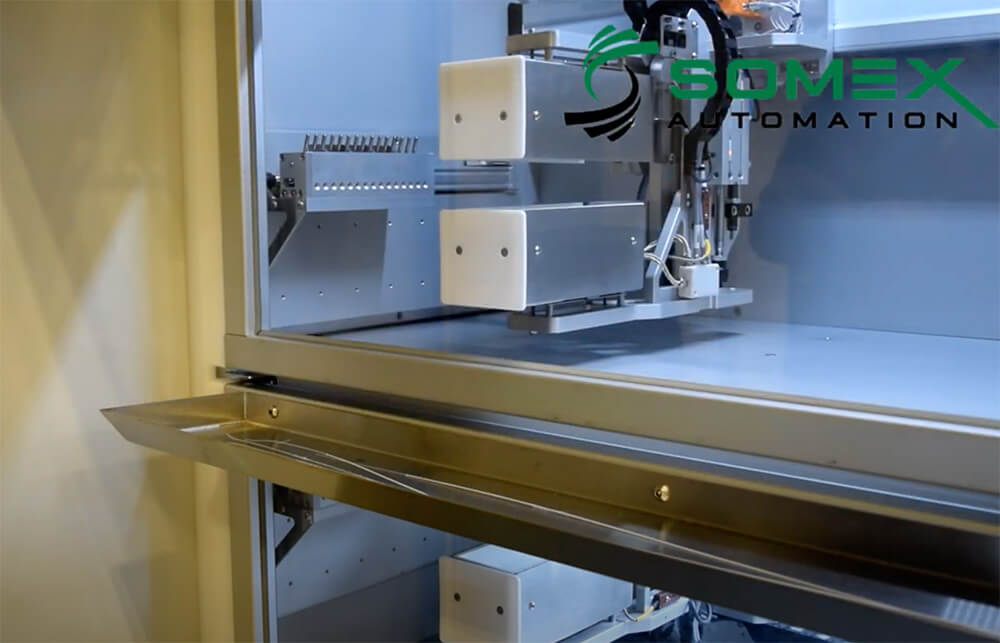

Double Deck Laminator

Laminate multiple catheter shafts simultaneously. https://www.youtube.com/watch?v=3mPM3siYRzQKey Features Automated Core Wire Stretching post-lamination to facilitate easy removal of Core Wire Catheter Shaft tooling automatically moves towards the operator to provide for […]

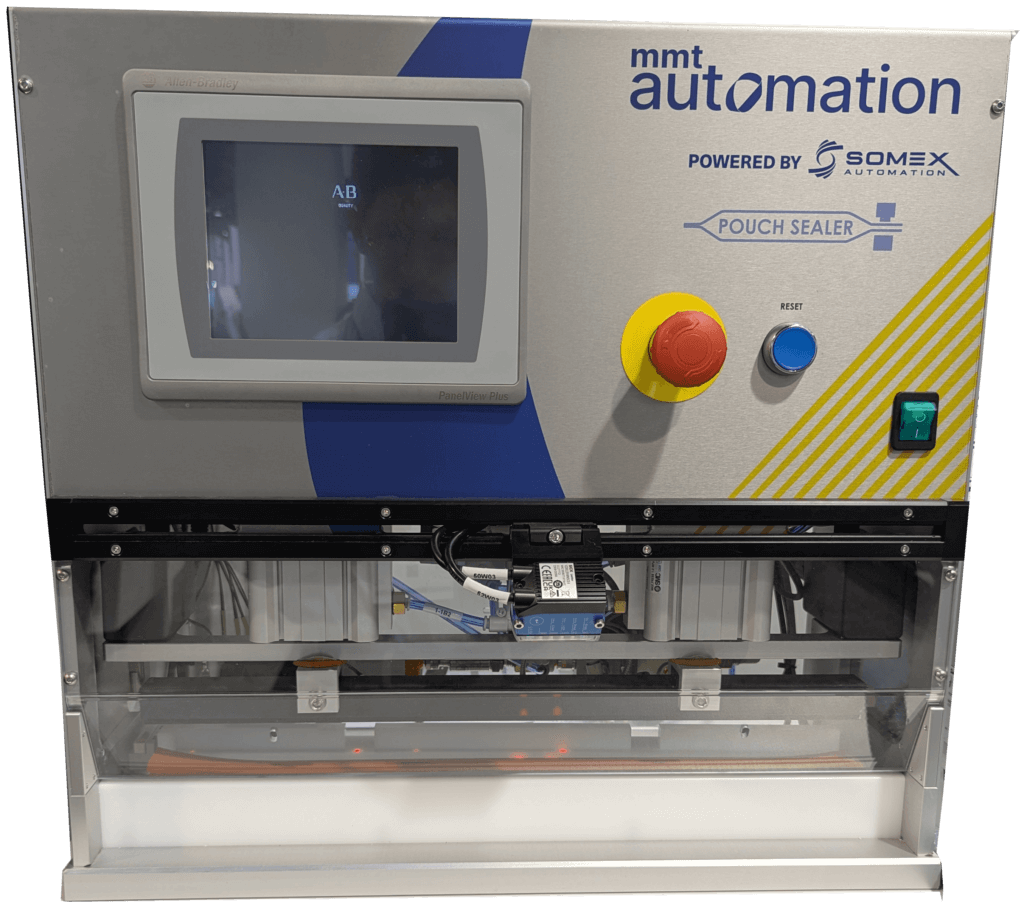

New Generation Bar Pouch Sealer (Model BPS-010)

The New Generation Bar Pouch Sealer (Model#: BPS-010) is a compact tabletop Bar Sealer, PLC controlled and interfaced with a label printer to control (poka-yoke) your pouch labeling and sealing […]

Automation Process

At MMT Automation, we follow a defined process flow for Equipment Development & Design; from Planning through Specification, Design, Construction, Testing & Installation. This process supports a typical Gamp5 Validation V-Model.

Hydrostatic Burst Tester

The Somex Automation High-Pressure Hydrostatic Burst Tester is a standalone unit using the hydrostatic principle, capable of generating test pressures in excess of 70 bar and burst testing a wide […]

Hot-Flo Heat Box

The Somex Automation Hot-Flo Heat Box is a benchtop Catheter Hot Air Nozzle System. The Heat Box features a digital readout of airflow, a ready lamp for temperature and airflow, […]

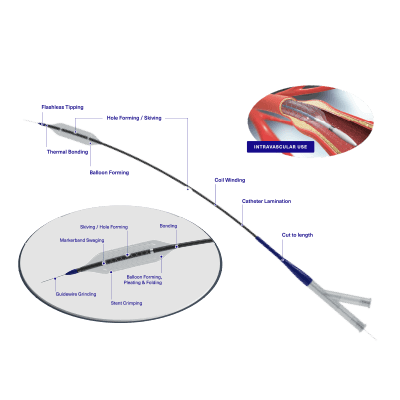

Balloon Catheter Infographic

Flashless Tipping Thermal Bonding Hole Forming/ Skiving Balloon Forming Coil Winding Catheter Lamination Cut to Length Bonding Skiving/Hole Forming Marker Band Swaging Guidewire Grinding Stent Crimping Balloon Forming, Pleating & […]

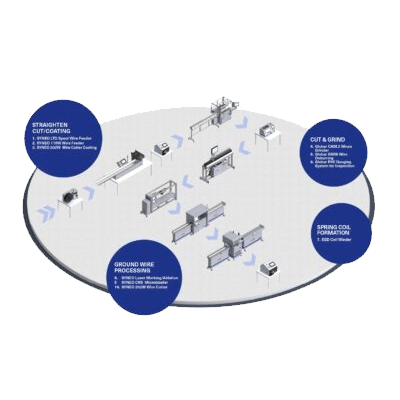

Total Guidewire Solutions

1 SYNEO LTD Spool Wire Feeder 2 SYNEO 110W Wire Feeder 3 SYNEO 202W Wire Cutter Coating 4 Glebar CAM.2 Micro Grinder 5 Glebar GSR6 Wire Deburring 6 Glebar P4K […]

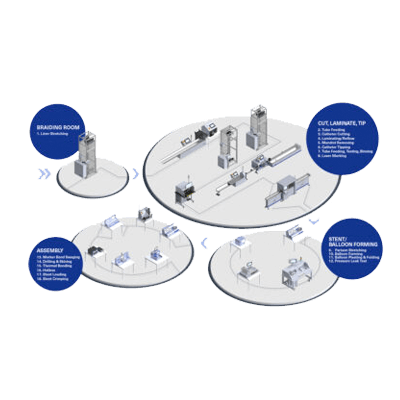

Catheter Manufacturing Process

1 Liner Stretching 2 Tube Feeding 3 Catheter Cutting 4 Laminating/Reflow 5 Mandrel Removing 6 Catheter Tipping 7 Tube Feeding, Testing, Binning 8 Laser Marking 9 Parison Stretching 10 Balloon […]