Punch FAQ

Cutting Tools – Frequently Asked Questions Have a question about SYNEO’s cutting tools? Leverage SYNEO’s 20+ years of application history and talk to an applications specialist today! What types […]

Accu-Cut 70M: Manual Medical Tubing Roll Cutter

The Manual Medical Tubing Roll Cutter trims rough-cut braided tubing to precise lengths with square, burr-free cuts. The 70M was designed to bring safe, ergonomic and precise braided tube cutting […]

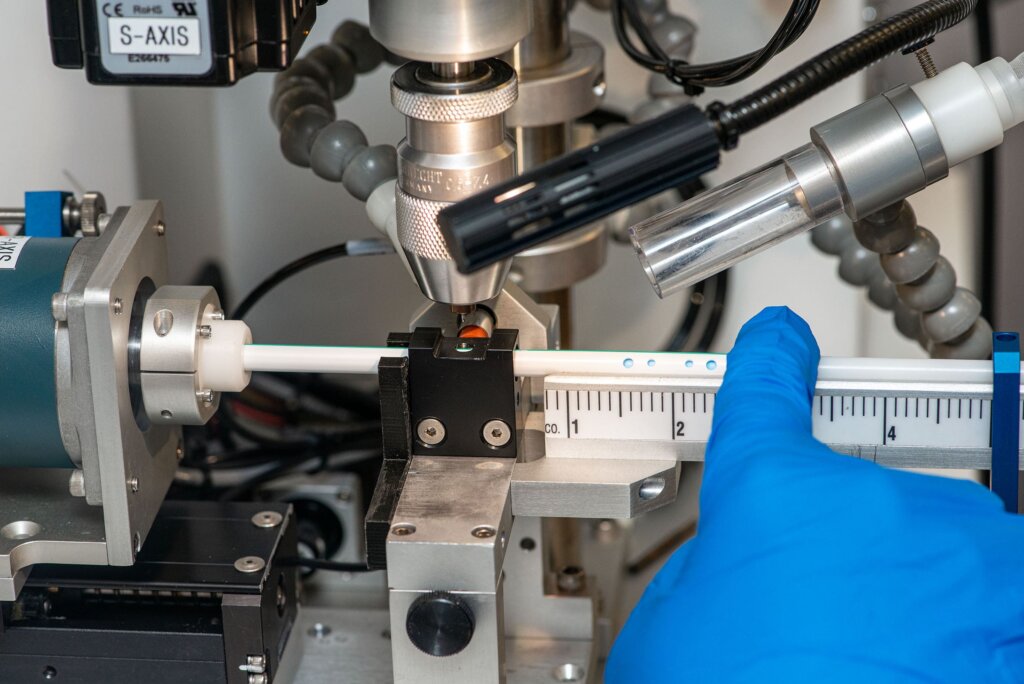

Accu-Test MIS: Mechanical Inspection Systems

SYNEO’s custom Mechanical Inspection Systems are utilized in applications requiring detection or quality assessments of surface roughness, typically found in combination with micro-blasting or other surface roughening applications. Key Features Reduced operator […]

Accu-Test VIS: Vision Inspection Systems

SYNEO’s custom Vision Inspection Systems are utilized in applications requiring detection or quality assessments of holes, marker bands, tip profiles and printed text or feature verification. SYNEO’s medical device visual inspection machines […]

Medical Precision Cutting Tools

With over twenty years of cutter development and hole-making experience, our applications team is equipped to satisfy the most-challenging hole dimension requirements. At MMT, our SYNEO brand manufactures medical […]

Device Assembly Services

At MMT we offer a host of medical manufacturing services, including device assembly services. As experts in the medical device manufacturing industry, we hold a competitive advantage with catheter component […]

Catheter Component Processing

At MMT, we are proud to offer top-notch services and support for catheter and guidewire manufacturing. Our services cater to a diverse range of OEMs and contract manufacturers. Whether you […]

Dual Feeding: Accu Feed DFS

The Dual-Feed system consists of two feeding processes mounted onto a high-quality, aluminum extruded, anodized rotary stand. This catheter manufacturing tube feeding machine provides precise alignment for variable cutting production. […]

Guidewire Jacketing System: Accu Feed GJS

The Guidewire Jacketing System automates the singulation, feeding, coating, inspection, and binning process around 3rd party extrusion systems. The machine features variable, programmable pulling speed capability that allows for high-resolution […]

Center Pick feeding: Accu Feed CPF

The SYNEO branded Center Pick Feeder targets similar applications as its well known counterpart the 110 Feeder but with a significantly smaller floor space requirement. This compact medical stick tubing […]

Guidewire Feeding: Accu Feed AGF

The Advanced Guidewire Feeder is the optimal wire feeding solution for centerless grinding processes. It improves production speed, accuracy, and quality while delivering a substantial return-on-investment. This medical centerless guidewire […]

Guidewire Feeding: Accu Feed 410 & 510

The 410 & 510 guidewire centerless grinder feeders handle wire for manufacturing processes such as guidewire centerless grinding, tip forming, bead blasting, or cleaning. The medical guidewire feeding machines are configurable […]

Dereeler: Accu Feed HPD

The Accu-Feed HPD High Performance Dereeler is similar to the Accu-Feed LTD in design and function. However, the HPD can handle a much larger spool as well as heavy gauge […]

Stick Feeding: Accu Feed 110

The dynamic Accu-Feed 110 Stick Tubing and Wire Feeder provides high speed, precise stick feeding of wire, metal and plastic tubing and metal rods for medical applications. This machine can […]

Dereeler: Accu Feed LTD

The Accu-Feed LTD Low Tension Dereeler is designed to provide constant strain, low tension payout of tubing to an Accu-Cut or other machine for high volume, critical tolerance manufacturing operations. […]

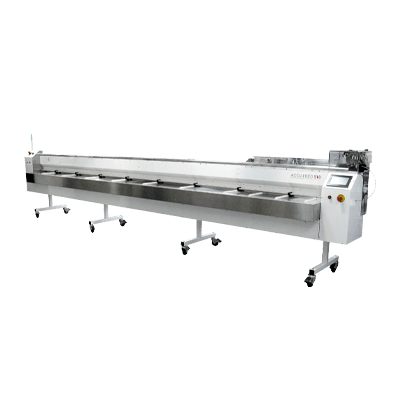

Automated Large Tube Cutting: Accu Cut CT & CTXL

The Accu-Cut CT Automated Large Tubing Cutter, based on the Accu-Cut 202L, is designed for applications that demand high traction and high power indexing. Ideal for part diameters measuring 0.400″ […]