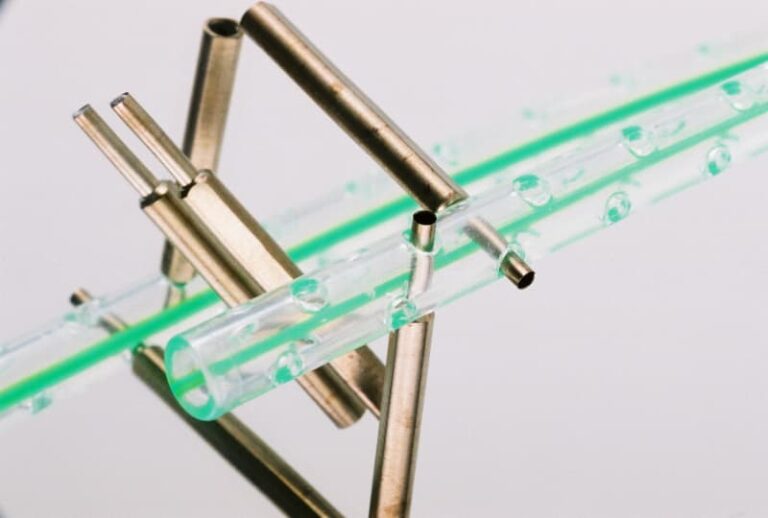

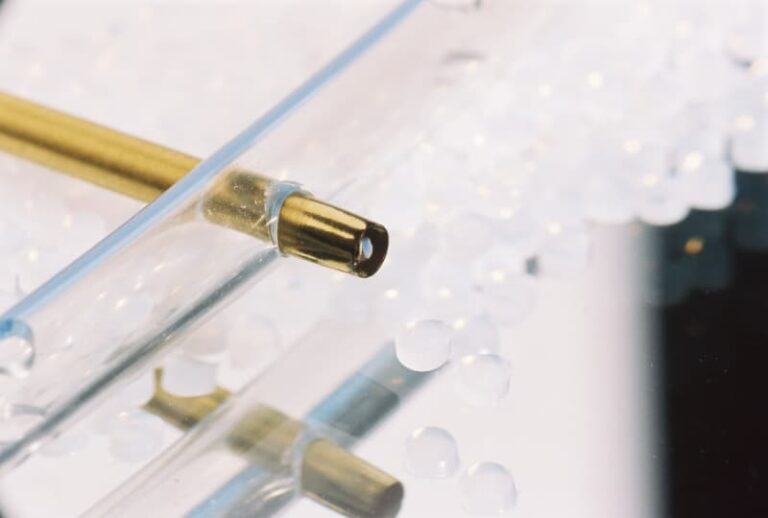

At MMT, we manufacture precision cutting tools with unparalleled sharpness for drilling holes, punching holes, and skiving holes in catheter tubing. Recognized globally as SYNEO cutting tools, we utilize proprietary Hollow Core Sharpening Technology to create flash-free, burr-free holes in flexible tubing applications as small as .005”. Take a moment to peruse our robust offering of hole-punching and drilling equipment designed to utilize these precision tools.

Our dedicated engineers will analyze the optimum blade raw material, tip style, dimensions, and coating to recommend catheter punches or coring blades to achieve the best hole quality and durability for each hole application. The SYNEO brand cutting tool products create optimal hole and skive configurations for tubing applications and remain the most economically viable mechanical hole-making solution available.

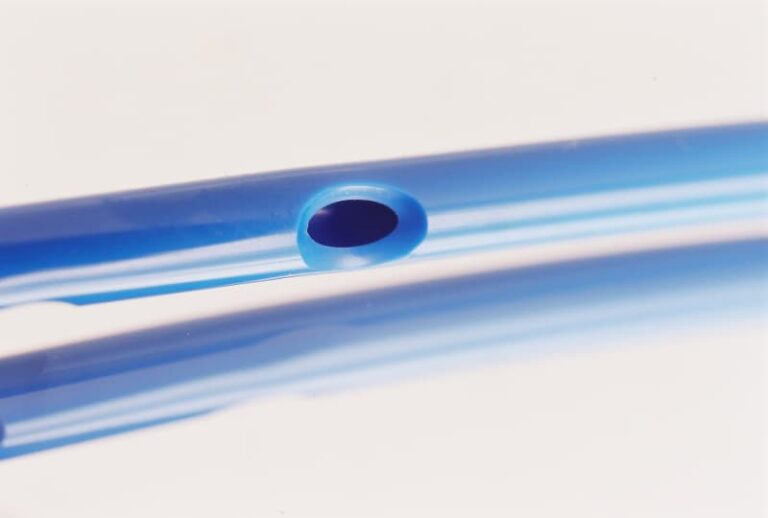

Punch Geometry

Our team is capable of manufacturing punching and coring blades in a variety of shapes depending on your specific application. Some of the common shape options include:

- Round

- Oval

- Formed

- Custom Geometry (i.e. Triangle, rectangle, diamond, etc.)

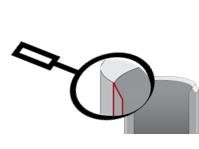

Tip Styles

All holes are not created equally, and the style of cutting edge directly impacts the taped and shape of the resulting hole. SYNEO’s sharpening process provides for three cutting tip profiles: Outside, Middle, and Inside.

OUTSIDE CUTTING EDGE

The outside edge has a straight outside diameter and a taper on the inside bore diameter, which yields a cutting edge at the outside diameter of the punch.

MIDDLE CUTTING EDGE

The middle edge is achieved by tapering the outside and inside diameter which yields a cutting edge approximately in the middle of the punch wall.

INSIDE CUTTING EDGE

The inside edge has a straight inside bore diameter and a taper on the outside diameter, which yields a cutting edge at the inside diameter of the punch.

Product Series By Material

C-Series | 304 stainless steel

C-Series hard temper, stainless steel punches are a cost-effective choice when applications require extremely sharp edges or resultant holes as small as 0.005” (0.15mm) in diameter. This series is available in a wide range of gauge sizes and can be further modified to yield different inside diameters, wall thicknesses and tip configurations. When application requirements are more demanding, the addition of a titanium nitride (TiN) coating increases durability and lubricity to the C-Series cutters.

B-Series | engineered metal

Combining highly engineered materials with precision manufacturing processes results in a robust line of cutters for braided catheter tubing applications. The B-series punches are available in a limited number of standard diameters or can be manufactured to meet specific requirements.

H-Series | 17-4 stainless steel

H-Series punches are furnace-hardened for maximum durability. This iron-chromium-nickel alloy couples high corrosion resistance with heat-treat capability for high strength. H-Series offer the best balance between cost and durability for automated punching, drilling and skiving applications with hole sizes greater than 0.020” (0.5mm).

T-Series | 465 stainless steel

Like the H-Series, these punches are furnace-hardened for maximum durability. These application-specific punches combine high strength, superior wear resistance and size availability to make them the practical choice for high-volume production or demanding applications.

Cutting Edge Coatings

Titanium Nitride (TiN)

Titanium Nitride is the most common coating recommended in tubing punch applications. TiN coating bonds molecularly with the metal surface to prevent blistering, flaking or chipping while substantially reducing friction and increasing material hardness for increased tool life.

TiN is particularly well-suited for razor-sharp SYNEO cutting edges because the micro-thin coating (two to three microns or .001 inches) adds toughness and durability without compromising cutting edge sharpness.

TiN coating:

- typically extends tool life five to seven times beyond a non-coated cutting tool

- will not corrode, blister, flake or chip

- will not leave residue

- is non-toxic and FDA-compliant for use in medical instruments

Featured Catheter Manufacturing Cutting Tool Applications

- Drainage Catheters

- Heart Diagnostic Catheters

- Neuro Diagnostic Catheter

- Injection-Molded Duckbill Components

- Odd-Form Respiratory Devices

Standard Punch List

| Nominal Cutting Edge (in) | Nominal Cutting Edge (mm) | Material | Shape | OD(in) | ID(in) | Length | Coating | Shaft | Wall | Tip Style | Part Number |

| 0.006 | 0.18 | 304SS | Round | .009 | .005 | 1.500 | TiN | 32 | Regular | Middle | CR0090055N32R4 |

| 0.011 | 0.28 | 304SS | Round | .014 | .009 | 1.500 | TiN | 28 | Custom | Middle | CR0140095N28R4 |

| 0.012 | 0.30 | 304SS | Round | .016 | .010 | 1.500 | TiN | 27 | Custom | Middle | CR0160105N27R4 |

| 0.016 | 0.41 | 304SS | Round | .020 | .013 | 1.000 | TiN | 25 | Custom | Middle | CR0200131N25T4 |

| 0.017 | 0.43 | 304SS | Round | .022 | .014 | 1.500 | TiN | 24 | Custom | Middle | CR0220145N24R4 |

| 0.022 | 0.56 | 304SS | Round | .028 | .018 | 1.500 | TiN | 22 | Custom | Middle | CR0280185N22R4 |

| 0.024 | 0.61 | 304SS | Round | .028 | .021 | 1.500 | TiN | 22 | Custom | Middle | CR0280215N22T4 |

| 0.026 | 0.66 | 304SS | Round | .032 | .022 | 1.500 | TiN | 21 | Custom | Middle | CR0320225N21R4 |

| 0.027 | 0.69 | 304SS | Round | .032 | .023 | 1.500 | TiN | 21 | Custom | Middle | CR0320235N21R4 |

| 0.029 | 0.74 | 304SS | Round | .035 | .025 | 1.500 | TiN | 20 | Custom | Middle | CR0350255N20R4 |

| 0.030 | 0.76 | 304SS | Round | .035 | .027 | 1.500 | TiN | 20 | Custom | Middle | CR0350275N20R4 |

| 0.034 | 0.86 | 304SS | Round | .042 | .029 | 1.500 | TiN | 19 | Custom | Middle | CR0420295N19R4 |

| 0.034 | 0.86 | 304SS | Round | .042 | .029 | 1.000 | TiN | 19 | Custom | Middle | CR0420291N19R4 |

| 0.035 | 0.89 | 304SS | Round | .042 | .031 | 1.500 | TiN | 19 | Custom | Middle | CR0420315N19R4 |

| 0.036 | 0.91 | 304SS | Round | .042 | .032 | 1.500 | TiN | 19 | Custom | Middle | CR0420325N19R4 |

| 0.036 | 0.91 | 304SS | Round | .042 | .032 | 1.000 | TiN | 19 | Custom | Middle | CR0420321N19R4 |

| 0.037 | 0.94 | 304SS | Round | .042 | .033 | 1.500 | TiN | 19 | Custom | Middle | CR0420335N19R4 |

| 0.037 | 0.94 | 304SS | Round | .042 | .033 | 1.000 | TiN | 19 | Custom | Middle | CR0420331N19R4 |

| 0.041 | 1.04 | 304SS | Round | .050 | .035 | 1.500 | TiN | 18 | Custom | Middle | CR0500355N18R4 |

| 0.042 | 1.07 | 304SS | Round | .050 | .036 | 1.500 | TiN | 18 | Custom | Middle | CR0500365N18R4 |

| 0.042 | 1.07 | 304SS | Round | .050 | .037 | 1.000 | TiN | 18 | Custom | Middle | CR0500371N18R4 |

| 0.043 | 1.09 | 304SS | Round | .050 | .038 | 1.500 | TiN | 18 | Custom | Middle | CR0500385N18R4 |

| 0.043 | 1.09 | 304SS | Round | .050 | .038 | 1.000 | TiN | 18 | Custom | Middle | CR0500381N18R4 |

| 0.045 | 1.14 | 304SS | Round | .050 | .042 | 1.500 | TiN | 18 | Custom | Middle | CR0500425N18R4 |

| 0.045 | 1.14 | 304SS | Round | .050 | .041 | 1.000 | TiN | 18 | Custom | Middle | CR0500411N18R4 |

| 0.050 | 1.27 | 304SS | Round | .058 | .044 | 1.500 | TiN | 17 | Custom | Middle | CR0580445N17R4 |

| 0.051 | 1.30 | 304SS | Round | .058 | .047 | 1.500 | TiN | 17 | Custom | Middle | CR0580475N17R4 |

| 0.055 | 1.40 | 304SS | Round | .065 | .049 | 1.500 | TiN | 16 | Custom | Middle | CR0650495N16R4 |

| 0.055 | 1.40 | 304SS | Round | .065 | .049 | 1.000 | TiN | 16 | Custom | Middle | CR0650491N16R4 |

| 0.062 | 1.57 | 304SS | Round | .072 | .055 | 1.500 | TiN | 15 | Regular | Middle | CR0720555N15R4 |

| 0.065 | 1.65 | 304SS | Round | .072 | .060 | 1.500 | TiN | 15 | Regular | Middle | CR0720605N15R4 |

| 0.072 | 1.83 | 304SS | Round | .083 | .065 | 1.500 | TiN | 14 | Regular | Middle | CR0830655N14R4 |

| 0.075 | 1.91 | 304SS | Round | .083 | .070 | 1.500 | TiN | 14 | Regular | Middle | CR0830705N14R4 |

| 0.079 | 2.01 | 304SS | Round | .089 | .073 | 1.500 | TiN | 13 | Regular | Middle | CR0890735N1354 |

| 0.084 | 2.13 | 304SS | Round | .095 | .076 | 1.500 | TiN | 13 | Regular | Middle | CR0950765N13R4 |

| 0.085 | 2.16 | 304SS | Round | .095 | .078 | 1.500 | TiN | 13 | Regular | Middle | CR0950785N13R4 |

| 0.096 | 2.44 | 304SS | Round | .109 | .087 | 1.500 | TiN | 12 | Regular | Middle | CR1090875N12R4 |

| 0.104 | 2.64 | 304SS | Round | .120 | .094 | 1.500 | TiN | 11 | Regular | Middle | CR1200945N11R1 |

| 0.117 | 2.97 | 304SS | Round | .134 | .106 | 1.500 | TiN | 10 | Regular | Middle | CR1341065N10R1 |

| 0.125 | 3.18 | 17-4 | Round | .125 | .113 | 1.500 | None | 1/8 in Shank | N/A | Outside | HS1251135P1183 |

| 0.187 | 4.75 | 17-4 | Round | .187 | .173 | 0.812 | None | 1/8 in Shank | N/A | Outside | HS1871730P1183S |

| 0.375 | 9.53 | 17-4 | Round | .375 | .348 | 0.812 | TiN | 1/8 in Shank | N/A | Outside | HS3753480P1183S |

| 0.500 | 12.70 | 17-4 | Round | .5 | .410 | 1.000 | TiN | 1/8 in Shank | N/A | Outside | HS5004101P1183 |