Balloon Catheter Manufacturing Technologies

At MMT, we understand the challenges and intricacies of balloon catheter manufacturing which is why we provide precision solutions that meet the demands of today’s minimally invasive interventional procedures using balloon catheter systems. We have the solutions for your balloon catheter manufacturing challenges – achieve the lowest profile size, increased inflation and deflation times, and precision trackability.

Balloon Catheter Forming

Our Catheter Balloon Forming equipment is designed with an innovative heating system that provides even heating and faster cycle times, empowering customers to increase production capacity without sacrificing quality.

We proudly introduce our latest balloon-forming innovations: the MPT BFMS-500-S2 with Rapid Heat Cool Mold and the NEW Interface BFM-5510 High Force for structural heart and high-pressure balloons.

MPT BFMS 500-S2

The Split Mold Balloon Forming Machine (BFMS-500- S2) has full servo control on the proximal and distal axis for precise and fast stretching of the parisons during the balloon-blowing process

MPT BFM 500-S2

The Center Mold Balloon Forming Machine (BFM-500- S2) has full servo control on the proximal and distal axis for precise and fast stretching of the parisons during the balloon-blowing process.

Interface BFM 3310

The Interface BFM-3310 Balloon Forming Machine is a computer-controlled system that expands upon a continued standard of excellence with ever-increasing capabilities and options.

Interface BFM 4410-3x

The Interface Model BFM-4410-x3 Computerized Balloon Forming Machine is a bench-top system, designed to handle a wide range of tubing sizes and materials.

Interface BFM 5510 HF

The Interface Catheter Solutions BFM-5510 High Force Balloon Forming Machine introduces advanced capabilities for manufacturing Structural Heart, Large Platform & Thick Wall High Pressure Balloons to the Interface BFM lineup.

Balloon Catheter Pleating & Folding

Wrap your balloon to the lowest possible profile with our precision pleating and folding or dual flute wrapping equipment.

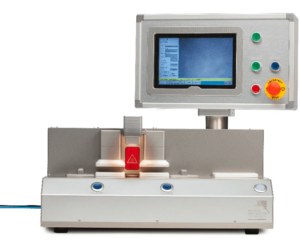

PTF-120-A

The PTF-120-A is a fully automated machine and can pleat and fold balloons with a length of approx. 100 mm. The balloon products are clamped on a stable product table with automatic positioning using stepper motors.

PTF-240-A

The PTF-240-A is a fully automated machine and can pleat and fold balloons with a length of approx. 230mm. The balloon products are clamped on a stable product table with automatic positioning using stepper motors.

PTF-240-M

The PTF-240-M is a robust and stable catheter balloon pleat and fold machine designed to provide the user with an effective and reliable production machine for pleating and folding catheter balloon products with minimal cost of ownership.

Parison Catheter Stretching

Stretch or neck down tube parisons in preparation for the balloon forming processes with our precision parison stretching equipment line. Uniform stretched tubing with repeatable results increases thruput.

The Interface CPS-1000 is a system designed to stretch or neck-down tubing parisons in preparation for the balloon forming process. It is easily programmable through the tilt touchscreen and capable of storing multiple program parameters with an operator lock-out option.

EDS

The Extrusion Die Stretching Machine performs hot die draw-down of plastic tubing used in catheter production. Three different models are available, 3×26, 3×68, and 3×80, letting you maximize your workspace based on the tube extrusion requirements.

PSM 400-SD

The PSM-400-SD parison stretcher is meticulously engineered to stretch parisons with unparalleled precision, ensuring uniformity and strength in every catheter produced.

The PSM-500-SD parison stretcher is meticulously engineered to stretch parisons with unparalleled precision, ensuring uniformity and strength in every catheter produced. Maximum stretch force of 500 N.

Stent Crimping - Balloon Catheter

Whether you’re manufacturing drug eluting stents – bioabsorbable stents – self expandable stents our flexible stent crimping systems allow you to successfully crimp stents onto the distal end of a balloon catheter after it is pleated and folded.

The CRF-200-PS is a stable stent crimping system with film protection for the processing of drug-eluting self-expandable stents. Fully enclose drug residue with our unique 4-film protection system combined with the stable MTP Europe BV 8-blade stent crimper design.

The CR-240-FSCP Flexible Stent Crimping Platform is developed for the crimping and transfer on or into the delivery system. Both balloon expandable and self- expandable stents up to 220 mm length can be handled.

The CR-240-SA Self-Expandable Stent Crimping Machine is developed for the crimping and transfer into the delivery system of self-expandable stents up to 200 mm length with a maximum diameter of approx. 30 mm.

The CR-150 Stent Crimping Machine is developed for the crimping and transfer into the delivery system of self-expandable stents up to 120 mm length with a maximum diameter of approx. 20 mm.

Bonding & Welding

Our machines provide accurately controlled heat to perform various tube-to-tube and balloon-to-tube bonds/welds with increased speed and accuracy.

The BT-NG machine is a thermal bonding machine based on the hot-jaw principle. The BT-NG has a maximum of four cavities that can be utilized at two different temperatures. The cavity position is software controlled.

The TBW-500 QX Tubing Welding Machine is a benchtop system that welds a variety of tubing sizes and materials. It is designed to weld similar polymer components such as inner lumen to distal shaft or balloon distal and proximal necks to the catheter shaft.

The ICS branded Heat Setting Oven, HSO-250, provides a cost-effective approach to improve fold memory retention after balloon fluting and wrapping by using lower temperatures over an extended time.

Hotbox

The CT HOTBOX configures with other CATH-TECH equipment products. The CT HOTBOX offers improved yields consistent with normal standards. It provides ideal product positioning of the thermal nozzle to give operators the capability to achieve highly precise tube and shaft bonds with increased reliability. It is useful in operating under strict process controls. Our Hotbox comes with compatible guide inserts, and modifications can be made on the Y and Z axis to refine accuracy and accommodate a wide variety of product configurations.

Hot-Flo Heat-Box

The Somex Automation Hot-Flo Heat Box is a benchtop Catheter Hot Air Nozzle System. The Heat Box features a digital readout of airflow, a ready lamp for temperature and airflow, and options for Enhanced Control & Monitoring of process parameters. It is available in two configurations: Compact and Umbilical.

Balloon Catheter Marker Band Swaging

Precision tracking is key to successfully navigating and deploying a balloon catheter through a patient. Adhering marker bands to a balloon catheter requires high performance equipment to achieve a smooth bond with no striations. Our technology was developed with patient well being in mind.

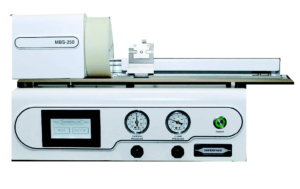

The ICS branded Marker Band Swager, MBS-250, is compact and clean-room ready with 360° swaging performance for gradual and smooth diameter reduction of marker bands for catheter production. The swaging equipment offers superior performance and no striations or deformations to the swaged parts.

Balloon Catheter Testing

The ICS gas pressure leak tester, model GPL-501, is a tabletop machine used for nondestructive leak testing of catheter components using dry nitrogen gas. Nitrogen gas is inert so there is no residue, water spots or water droplets on catheter components, making it ideal for testing of finished devices.

The Interface Gas Pressure Leak Tester, Model GPL-5020, is designed for rapid, non-destructive testing of catheters. The system can also perform vacuum leak testing of catheter/stent assemblies to verify the integrity of a balloon after stent crimping.

The ICS Hydraulic Pressure Testers provide critical hydraulic test functions for balloon catheters and components, including tubing and balloons. The HPT-1000 is easily programmable with a high visibility vacuum florescent display and four navigation keys.

The PT-3070 is ideally suited for testing small plastic pressure retaining components such as welded or bonded plastic components and tubing assemblies that are typically encountered in many disposable medical devices, i.e. balloon catheters.