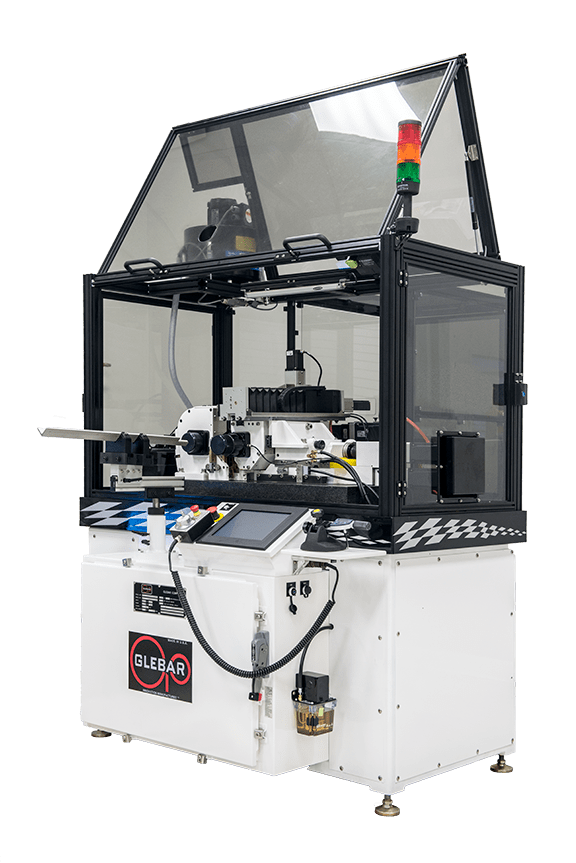

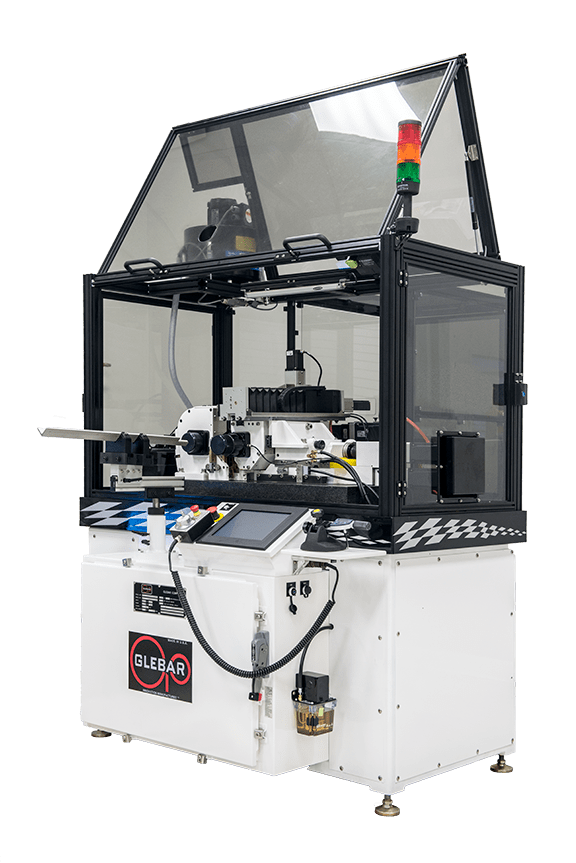

Steel Spring Cup (2 Parts Per Second | Zero Defect) | GT-610

Challenge: To design a fully automated turnkey feeding and inspection solution, integrated into to a Glebar GT-610 Thrufeed Grinder that ensures a one hundred percent defect-free product that is ground to […]

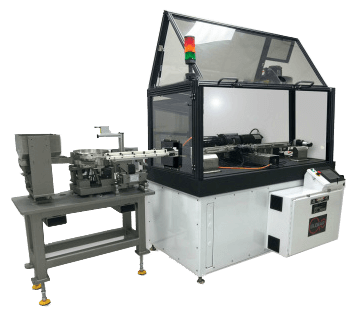

Valve Seat | GT-610

Challenge: To auto thrufeed grind metal valve seat components which are used in the automotive industry. The customer needed a system which could accurately grind and gauge 3,000 parts per hour. […]

Cutting Multiple Steel Bars with Precision Abrasive Cutoff Machine Reduces Production Time for Aerospace Fastener Manufacturers | CS1-A

Current Process Conventional cutting processes use an abrasive chop saw, band saw, lathe cutoff, or shear cutting machine. Each method has its disadvantages. Tooling wears quickly and is expensive, driving […]

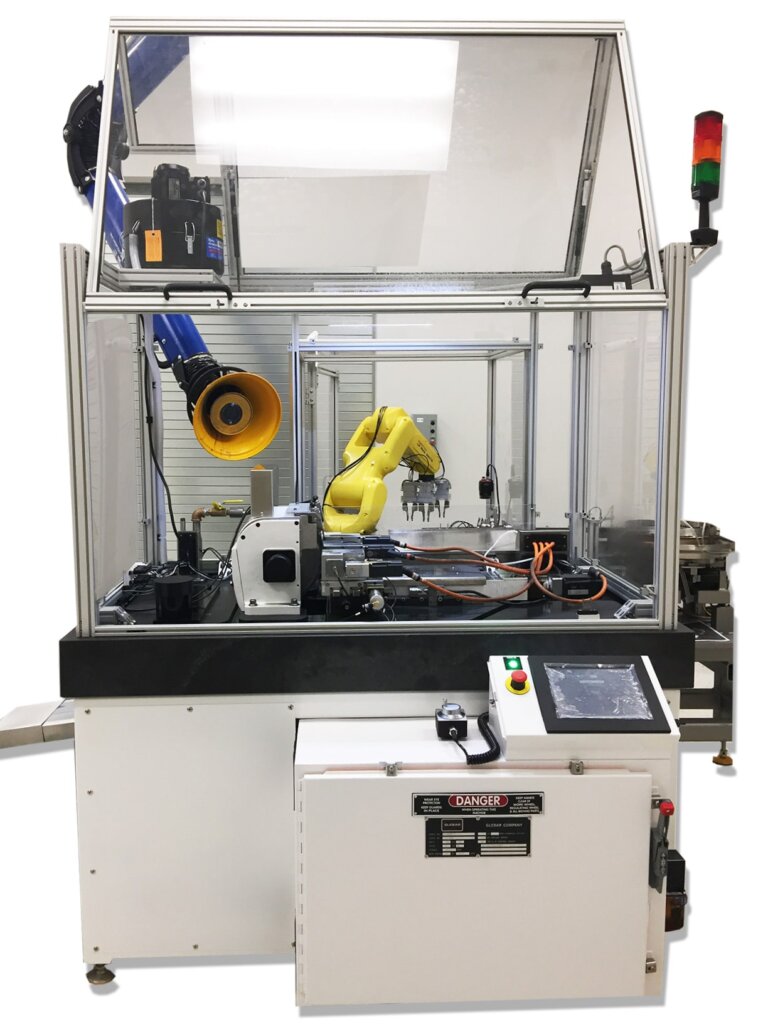

Automotive Solenoid | GT-610

Challenge: To thrufeed automatically thru feed grind an automotive component and achieve a 1.2 Rz surface finish Solution Using a GT-610 thrufeed machine coupled with a vibratory feeding system that oriented […]

Aerospace Fasteners | GT-610 CNC

Challenge: To grind diameters on parts of many sizes and lengths for a manufacturer of aerospace fasteners. The goal was to provide a solution that gave the customer a machine with […]

Composite Strips | DD-7

Challenge: To grind both sides of composite strips (fiberglass), fully automated at high speed with tight tolerances. Solution Using Glebar’s DD-7 Double Disc Grinder (one of the smallest on the market), […]

Thrufeed Grinding Steel Tubes | TF-9DHD

Manufacturers use grinding machines with a narrow work wheel requiring several passes to reduce the diameter and achieve acceptable surface finish. Thus creating longer cycle times. Machines are difficult to […]

Steel Taps | GT-610 CNC

Challenge: Customer wants to increase output for steel taps used to drill threaded holes as used in the machining and tooling industry. In addition to speeding up the throughput time, achieving […]

Carbide Rods (Tungsten) | PG-9X20DHD

To establish a process whereby pre-sintered carbide drill blanks processed in a hot isostatic press (HIP) can be pre-sized to produce straight rod stock for long blanks. The existing method […]

Tungsten Carbide Pin (Roughing) | PG-9DOD

Challenge: The customer wants to decrease cycle time while maintaining tight concentricity specifications for roughing a tungsten carbide pin. Solution The Glebar PG-9DOD addressed the challenge. The system was configured with dual […]

Tungsten Carbide Pin (Finishing) | GT-610

Challenge: Satisfying the high volume finishing requirements for the complex form geometry on a hard carbide pin application. This compliments the PG-9DOD Carbide Pin Roughing Operation. Solution Solution: The Glebar GT-610 Infeed […]

Precision Punches | GT-610 CNC

Challenge: To grind a variety of tooling punches to extreme precision, while accommodating small lot sizes with short changeover times. Solution Hydraulic punch machine tooling goes through punishment when forming and […]

Burnishing Tools | GT-610 CNC

Challenge: To grind burnishing and expander rolls used in manufacturing tubes for a multitude of applications ranging from oil and gas tubes to automotive. Due to the shape of the parts […]

Titanium & Steel Rods | GT-610

Challenge: Quality, cost control, and lead time issues of outsourcing the pre-sizing of titanium and steel bars. Solution A GT-610 machine equipped with a wide 8-5/8” super abrasive grinding wheel […]

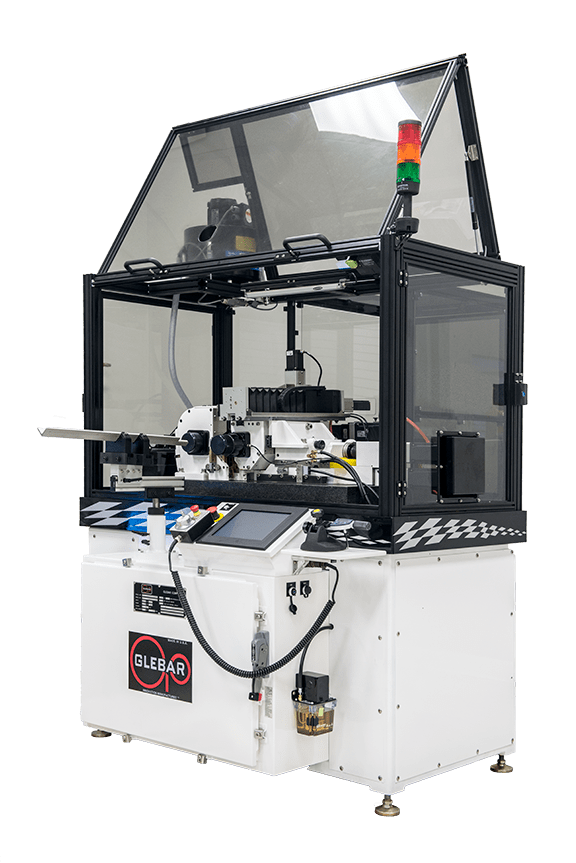

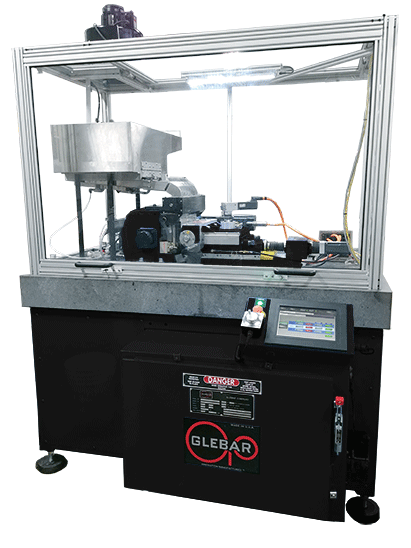

Enhanced Throughput and Pinpoint Precision Elevate Form Grinding on Glebar’s New PG-912DG Enclosed Centerless Form Grinder

Glebar’s Applications Division conducts research and development of innovative cutoff and grinding technology. Their most recent focus was to innovate the existing design of our PG-9 series of Centerless Plunge […]

Form Grinding of Deodorant Balls | PG-9BHD

Challenge Manufacturers use lapping machines which are unable to hold consistent tolerances or capacity, creating inconsistent surface finishes and longer cycle times. Provide a form grinding solution for 1″ and […]