Grinding Technologies

Precision Centerless and Electrochemical Grinding Technologies

Achieve high-volume production without sacrificing precision. Our precision grinding technologies combine compact design with powerful performance, making them ideal for manufacturers who require speed, accuracy, and reliability in every cycle. Built for demanding applications, our space-saving electrochemical (ECG) and centerless grinding machines are engineered to reduce costs and maintain the tight tolerances today’s medical, automotive, aerospace, defense, and general industrial applications require.

From guidewires and Nitinol tubing to ceramic shafts, carbide rods, fasteners, and beyond, our grinding technologies support a wide range of components from a variety of industries. Whether you're scaling production or refining a complex process, we deliver tailored, turnkey systems designed to meet your exact specifications.

TF-9DHD Infeed/Throughfeed Centerless Grinder

The TF-9DHD Infeed/Throughfeed Centerless Grinder uses computer controls to grind both hard and soft materials including catheters, medical guidewires, and spinal cord stimulators. Inside the compact footprint is a 15HP main spindle motor powering an 8.625” wide work wheel combining to remove more material faster, and with better surface finishes, than similar machines with narrower grinding wheels. The TF-9DHD is designed to enhance productivity through a simple control interface and automation integration.

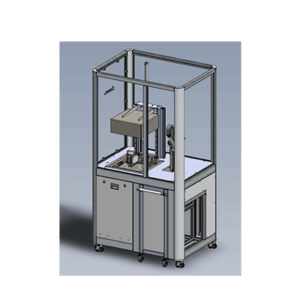

CAM.2 Micro Grinder

The CAM.2 Micro Grinder can produce flats, radiuses, needle points, and non-linear shapes; the perfect machine to grind complex medical guidewires, dental parts, and small precision parts for various industries. Combining the latest in multi-axis servo motor control, submicron positioning, and an intuitive 15″ HMI, the CAM.2 offers unmatched performance. With the CAM.2’s full-fledged G-code underpinnings, direct integration with CAD/CAM packages is seamless. Previously unproduceable parts can be made easily, with minimal setup time, and with limited operator training.

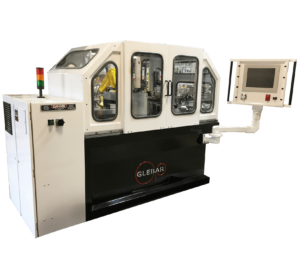

GT-610 Centerless Grinders

The Glebar modular GT-610 Series of precision Infeed/Thru-feed Centerless Grinders remove more material faster, and with better surface finishes than competing machines. Applications for machines within this series include aerospace fasteners, automotive transmission components, engine parts, and valve stems, PCD drill bits, arthroscopic bone shavers, bone drill blanks, medical device components, and more.

Search By

Technologies

or Brand.

Applications | Technologies

Brands

Needle Point Grinding using ECG | PGS-100

Challenge Converted OD grinders with custom tooling and soft grinding wheels all of which wear at a high rate. Setup and changeover time is significant and requires extensive mechanical adjustments.

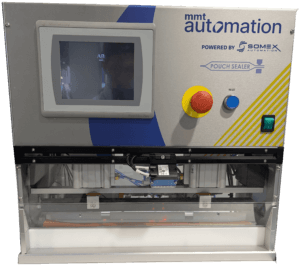

New Generation Bar Pouch Sealer (Model BPS-010)

The New Generation Bar Pouch Sealer (Model#: BPS-010) is a compact tabletop Bar Sealer, PLC controlled and interfaced with a label printer to control (poka-yoke) your pouch labeling and sealing

NEW! Flex-Drill for Catheter Holes

We’ve been encouraged to see our customers thriving and busy with so many new developments – thank you for letting us be a part of your success. Speaking of new

Offline CNC Grinding Wheel Dresser Improves Grinder Efficiency | DM-9CNC

The DM-9CNC Wheel Dressing Machine allows a grinding wheel to be contour dressed offline using a fully programmable single diamond or rotary diamond roll. Having the ability to dress wheels

P4K: Profile Metrology System

The Glebar P4K Gauging System is the world’s fastest and most accurate profile metrology system available for long parts or multiple short parts. It is the industry standard for measuring

P5K Gauging System

5-Year Extended Limited Warranty with Special Pricing through Nov. 30, 2025! MMT’s Glebar P5K Gauging System provides medical device and industrial manufacturers with the fastest and most precise scanning and

Parison Stretching: PSM 400-SD

Parison stretching is an integral part of balloon blowing. Therefore Medical Production Technology Europe BV has put its innovative design capability into the build and design of the PSM-400-SD parison

Parison Stretching: PSM 500-SD

Parison stretching is an integral part of balloon blowing. Therefore Medical Production Technology Europe BV has put its innovative design capability into the build and design of the PSM-500-SD parison

PG-9CRG: OD Grinding System

https://www.youtube.com/watch?v=d_S70nJZPpU The Glebar PG-9CRG OD Grinding System is a compact machine that shapes the diameter on parts where the diameter of the piece is concentric to the centerline of the

PG-9DOD: Compact OD Grinding Machine

The Glebar PG-9DOD is a compact OD grinding machine designed to handle small components requiring a tight concentricity such as rollers, pins, bushings, and other engine components. Designed to grind

PG-9X20DHD: Form Grinding Machine

The Glebar PG-9x20DHD centerless form grinding machine was designed to form ceramic components such as unfired carbide and crystal quartz glass boules used to produce fiber optics by Form Grinding

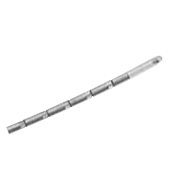

Pinion Shafts | GT-610

Challenge: To devise a new process for an automotive component manufacturer to automatically grind and gauge pinion shafts for differentials. The shafts are made of hardened steel. The Customer is looking

Pleating & Folding: 240 M

Robust and stable catheter balloon pleat and fold machine designed to provide the user with an effective and reliable production machine for pleating and folding catheter balloon products with minimal

Pleating & Folding: PTF 240 A

The PTF-240-A is a fully automated machine and can pleat and fold balloons with a maximum length of 230 mm. The balloon products are clamped on a stable product table

Pleating & Folding: PTF 120

The PTF-120 is a fully automated machine and can pleat and fold balloons with a length of approx. 100 mm. The balloon products are clamped on a stable product table

Pleating & Folding: PTF 120 A

Description The PTF-120-A is a fully automated machine and can pleat and fold balloons with a length of approx. 100 mm. The balloon products are clamped on a stable product

Polycrystalline Diamond (PCD) Cutter | GT-610 SD

Challenge: To process carbide and polycrystalline diamond with complete automation, conserving grinding wheels and using little power, all on a machine within a small footprint Solution Glebar’s GT-610-SD uses machine intelligence

Precision Cutting Tools

At MMT, we manufacture precision cutting tools with unparalleled sharpness for drilling holes, punching holes, and skiving holes in catheter tubing. Recognized globally as SYNEO cutting tools, we utilize proprietary

Precision Punches | GT-610 CNC

Challenge: To grind a variety of tooling punches to extreme precision, while accommodating small lot sizes with short changeover times. Solution Hydraulic punch machine tooling goes through punishment when forming and

Printing System: Accu Blast

Surface modification through sandblasting can be an excellent alternative to traditional depth mark printing on catheters or guidewires. These same surface modification processes can also be leveraged for increase adhesion

Printing System: Accu Print

SYNEO Accu-Print Catheter Printing Systems combine SYNEO’s best-in-class tubing materials handling and inspection techniques with pad and inkjet printing functions to meet precision printing specifications for unique medical devices. Accu-Print

ProCenter Plus

Features | Accessories | Specifications Designed specifically for MicroBlasting, ProCenter Plus combines a compact dust collector and chair-height work chamber in one freestanding unit, creating a clean, comfortable work environment

Punches: Surgical Punches

For tissue cutting, suture cutting and coring applications, SYNEO works closely with OEMs and contract manufacturers to design and develop cutter criteria for sharpness, incision dynamics, and durability. https://www.youtube.com/watch?v=cNBshcRw3s0 SYNEO’s

Radio Frequency Pigtail Curling

SPOTLIGHT ON: Pigtail Curling Process on RF Tipping Machines CATHTIP Radio Frequency tipping machines utilize precise closed-loop temperature control, allowing equal accuracy whether modifying delicate, thin-walled material or robust thick-walled

Revisiting Relationships in Full-Service Outsourcing

Medical Product OutsourcingOriginally Published: April 29, 2025 Author: Sean Fenske, Editor-in-Chief (MPO) Given recent challenges, both OEMs and CMOs are reviewing their partnerships and adjusting as necessary to improve the arrangement.

RF Catheter Tipping

Your projects are in capable hands at CATHTIP. The teams creating your proof-of-concept catheter parts, prototypes and development processes are intimately acquainted with the best, most versatile, powerful machines on

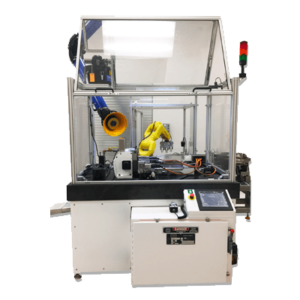

Robot Automated Catheter Tips & Holes

Thank you to all who stopped by to visit with us at MD&M West. Our engineers love discussing your projects and developing solutions. Guests viewed superior catheter tipping and hole

Rod and Filament Extrusion

Rods, filaments, and beading are solid extrusions that are typically round and small in diameter. Rods and filaments can also be extruded with a rectangular profile. Filaments are added to

Roll Cutters

MMT’s FePeeler Roll Cutters set new standards in catheter production. Effortlessly achieve precise cuts on braided tubes, ensuring cleanliness, consistency, and quality at every stage of production. MRC-1 Request A

RVG 10 Electrochemical Rotary Vertical Grinder

New Product! The Tridex RVG-10 Electrochemical Rotary Vertical Grinder is specifically designed for grinding the inside and outside of stepped honeycomb diameters of aircraft engine components. Engineered with heavy-duty cast

Secure Legacy Machines by Upgrading to Windows 10 | GT-9AC

Current Process: Machines that run on outdated operating systems such as Windows XP or Windows 7 are more vulnerable to malware, viruses, and other security issues. Microsoft no longer supports

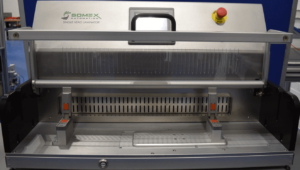

Single Head Laminator

MMT’s Somex Automation Single Head Laminator is a compact versatile tabletop Hot Air Nozzle Horizontal Laminator System. It features digital control of airflow, a ready lamp for temperature & airflow,

Single Lumen Tubing

Single lumen tubing are extrusions that contain one channel, or passage, through the center of it’s length. Single lumen extrusions are commonly used in medical applications where only one channel

Speciality Manufacturing

Delivering Unmatched Precision and Quality in Catheter Manufacturing At MMT, our top-tier team specializes in the meticulous crafting of catheters and medical components, focusing on essential processes such as tipping,

Spinal Cord Stimulation Devices | TF-9DHD

Challenge: To size implantable spinal cord stimulation devices that deliver precise doses of electricity to targeted nerve sites for patients suffering from chronic back problems. The device is long and flexible,

SPOTLIGHT ON: EXPANDED OFFERINGS & HIGH DEMAND

The neurovascular and cardiovascular catheter markets have exploded, and with that we are seeing an increased need for our best-in-class catheter tipping and hole-forming solutions. At CATHTIP, we encourage our

SPOTLIGHT ON: FLARING PROCESS

Technology is advancing at record-breaking speeds, and processes that worked in the past may not be the most effective today. That’s why at CATHTIP, we dedicate our efforts to providing

SPOTLIGHT ON: MD&M WEST 2022

We are excited to showcase our state-of-the-art catheter manufacturing technologies at MD&M West, April 12-14. Join us at booth #3101 where we will feature our Magnum Tube-Forming Machine, FLEX-Drill Hole-Forming

SPOTLIGHT ON: MICRO FLARING & SPECIALTY MANUFACTURING SERVICES

CATHTIP Your source for Specialty Manufacturing and leading edge drills with flow through technology. We understand that sourcing capital equipment may not be a viable option for proof of concept

Stainless Steel Bone Pins | GT-610 CNC

Challenge: The customer is looking for a turnkey, one-operation automated process allowing a single-pass solution for Stainless Steel Bone Pins, for example. Solution Able to hold extreme tolerances and fitted