Grinding Technologies

Precision Centerless and Electrochemical Grinding Technologies

Achieve high-volume production without sacrificing precision. Our precision grinding technologies combine compact design with powerful performance, making them ideal for manufacturers who require speed, accuracy, and reliability in every cycle. Built for demanding applications, our space-saving electrochemical (ECG) and centerless grinding machines are engineered to reduce costs and maintain the tight tolerances today’s medical, automotive, aerospace, defense, and general industrial applications require.

From guidewires and Nitinol tubing to ceramic shafts, carbide rods, fasteners, and beyond, our grinding technologies support a wide range of components from a variety of industries. Whether you're scaling production or refining a complex process, we deliver tailored, turnkey systems designed to meet your exact specifications.

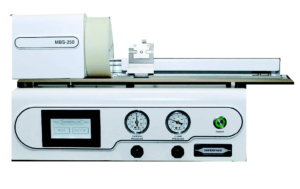

TF-9DHD Infeed/Throughfeed Centerless Grinder

The TF-9DHD Infeed/Throughfeed Centerless Grinder uses computer controls to grind both hard and soft materials including catheters, medical guidewires, and spinal cord stimulators. Inside the compact footprint is a 15HP main spindle motor powering an 8.625” wide work wheel combining to remove more material faster, and with better surface finishes, than similar machines with narrower grinding wheels. The TF-9DHD is designed to enhance productivity through a simple control interface and automation integration.

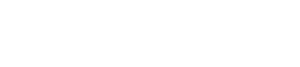

CAM.2 Micro Grinder

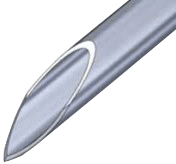

The CAM.2 Micro Grinder can produce flats, radiuses, needle points, and non-linear shapes; the perfect machine to grind complex medical guidewires, dental parts, and small precision parts for various industries. Combining the latest in multi-axis servo motor control, submicron positioning, and an intuitive 15″ HMI, the CAM.2 offers unmatched performance. With the CAM.2’s full-fledged G-code underpinnings, direct integration with CAD/CAM packages is seamless. Previously unproduceable parts can be made easily, with minimal setup time, and with limited operator training.

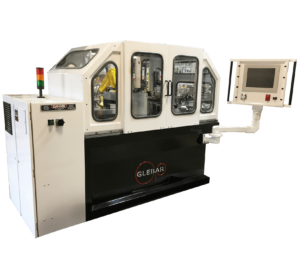

GT-610 Centerless Grinders

The Glebar modular GT-610 Series of precision Infeed/Thru-feed Centerless Grinders remove more material faster, and with better surface finishes than competing machines. Applications for machines within this series include aerospace fasteners, automotive transmission components, engine parts, and valve stems, PCD drill bits, arthroscopic bone shavers, bone drill blanks, medical device components, and more.

Search By

Technologies

or Brand.

Applications | Technologies

Brands

Hole Drilling: Accu-Drill MD & MP

The Manual Hole-Making solutions punch or drill precision holes in a variety of extruded tubing and injection molded applications. These manual catheter hole punching and manual medical tubing drilling machines

Hole Drilling: Accu-Drill SD

The Automated Catheter Hole Making solutions are powerful and safe solutions to hole-making needs of various shapes and sizes. Four models, ranging from one to four axes, allow for repeatable

Hole Forming: 400 Series

Save time and money when catheter hole drilling with the CATHTIP branded automated catheter hole punch machines. Make clean and fast catheter holes with this tabletop, four axis stepper motor-controlled

Hole Forming: Cathtip Flex Drill

Flex-Drill by CATHTIP is the most flexible, cost-effective option for hole forming in catheter prototypes and early development applications. The drill can be mounted or handheld and operated by a foot

Hot-Flo Heat Box

The Somex Automation Hot-Flo Heat Box is a benchtop Catheter Hot Air Nozzle System. The Heat Box features a digital readout of airflow, a ready lamp for temperature and airflow,

How Grinding Technology Shapes Modern Medical Device Manufacturing

The Precision Powerhouse Behind Modern MedTech Manufacturing In the early days of medical device manufacturing, grinding was largely a manual skill. It was slow, labor-intensive and dependent on the unreliable

Hydraulic Pressure Tester: HPT-1000

The Hydraulic Pressure Testers provide critical hydraulic test functions for balloon catheters and components, including tubing and balloons. The HPT-1000 is easily programmable with a high visibility vacuum florescent display

Hydraulic Pressure Tester: HPT-3070

The PT-3070 is ideally suited for testing small plastic pressure retaining components such as welded or bonded plastic components and tubing assemblies that are typically encountered in many disposable medical

Hydrostatic Burst Tester

The Somex Automation High-Pressure Hydrostatic Burst Tester is a standalone unit using the hydrostatic principle, capable of generating test pressures in excess of 70 bar and burst testing a wide

Improving operator and machine efficiencies through automatic work wheel dressing | TF-9DHD

Current Process Hydraulic dress cycles require high operator input reducing their efficiency. The traverse rate of the dressing tool is difficult to establish affecting surface quality. Inconsistent dressing of the

Increase Memory for Programming with Companion Software from Tridex Technology | CS1-EA

Current Process CS1 machines can store up to 100 setups, and PLC controlled SG machines can store up to 30 setups. This limits how many programs can be stored and

Increase Productivity by Cutting Zirconium Tubes with ECG | CS1-E

Current Process Zirconium tubes are cut one at a time using carbide tools on a lathe. A lathe cutoff leaves burrs requiring deburring to achieve a smooth surface finish. Carbide

Increase Uptime by Controlling Work Wheel Speed to Effectively Utilize Super-Abrasive Wheels | GT-9AC

Current Process Super-abrasive grinding wheels require faster speeds to run effectively. Main machine spindles can have fixed speeds, limiting their ability to use CBN or Diamond grinding wheels. A fixed speed

Infeed/Thrufeed Centerless Grinder: GT-610

The Glebar GT-610 Infeed/Throughfeed Precision Centerless Grinder features a compact design that provides high horsepower, high rigidity, and superior slide positioning. Customizable controls are designed to integrate full turnkey automation

Infeed/Thrufeed Centerless Grinder: GT-610 CNC

The Glebar GT-610 CNC Infeed / Throughfeed Precision Centerless Grinder is the complete “lights-out” solution for applications where a high degree of automation, data gathering, and gauging feedback is required.

Infeed/Thrufeed Centerless Grinder: GT-610 SD

The Glebar GT-610 SD is a Thrufeed/lnfeed Centerless Grinder designed to grind supermaterials such as polycrystalline diamonds and other hard materials where the process is unknown and challenging. This machine

Infeed/Thrufeed Centerless Grinder: GT-610M

Built for the machine shop, the GT-610M Thrufeed Centerless Grinder is an affordable, compact, precision centerless thrufeed grinding machine. Featuring its 8-5/8″ wide x 10″ diameter work wheel, it can

Interface Catheter Solutions (ICS) Manufacturing Location Change FAQs

Interface Catheter Solutions – FAQ – Manufacturing Location Change Notification 1. Why is Interface Catheter Solutions relocating its facility? As part of our ongoing commitment to continuous improvement and operational

Irregular Shapes – Bulb Tipping Process

SPOTLIGHT ON: IRREGULAR-SHAPED TIPPING You are NOT limited by simple tapers on our Magnum & Quantum tipping machines. Your irregular-shaped tips can be proven out, improved, & developed for production with

JetCenter

Features | Accessories | Requirements | Specifications In an evolution of our automated MicroBlasting platform JetCenter has created new options. In addition to having greater travel, this system was designed

Laser Measurement System (LMS)

Interface Catheter System Model LMS-100 is a bench-top measurement system designed specifically for catheter balloons. The system offers a non-contact solution to the typical problems encountered in the dimensional measurement

LBS6000 Catheter Laser Bonder

Innova Design is now an MMT Company: Learn More! MMT’s LBS6000 Catheter Laser Bonder, powered by Innova, provides superior ergonomics and innovative laser safety features with advanced hardware and software

Liner Stretcher

The CATH-TECH™ Liner Stretcher uses a combination of heat and tension to process a liner to a fixed mandrel. This automated process eliminates the need for the operator to hand stretch

Manual machine grinding steel tubes for the medical industry replaced with a CE Certified micro grinder | TF-9DHD

Challenge Numerous manufacturers around the world find themselves with legacy equipment incapable of meeting the changing environmental and safety standards recommended by regulatory standards. The customer in this case was operating

Manual Orthopedic Pin Manufacturing Process Converted to Automated with 100% QC | GT-610

Challenge The operator would manually feed the stainless steel orthopedic pins into the centerless grinder then manually clean and gauge each pin. Manual input and adjustment were required during the

Manual Skivers

Manual skivers are ideal for low-volume, small-batch manufacturing and prototyping where precision and control matter most. Proudly Made in the USA from durable 300 series stainless steel, MMT’s FEPeeler® manual

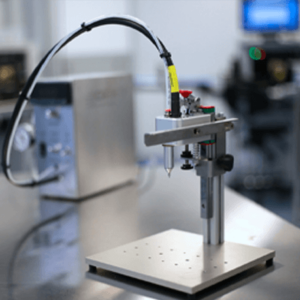

Marker Band Swager: MBS-250

The Interface Catheter Solutions branded Marker Band Swager, MBS-250, is compact and clean-room ready with 360° swaging performance for gradual and smooth diameter reduction of marker bands for catheter production.

Materials

NYLON Rilsamid® – 70D AESNO MED Rilsan® – 71D BESNO MED VESTAMID® Care ML – N/A ML (16, 18, 21, 24, 94) Grilamid TR® – 82D-85D TR-(55, 90) PEBA Polyether block

MCS-12 Single Axis Burr-Free ECG Cutoff Machine

The Tridex MCS-12 Single Axis Burr Free Electrochemical (ECG) Cutoff Machine features completely burr-free cutting, virtually eliminating the need for deburring or other corrective secondary operations and reducing scrap. Almost

Medical Bone Drill (Gauging | P4K)

Challenge: Lack of a clear, simple method to inspect the geometric profile of many components. Existing systems are slow, unreliable, and complex to operate. Solution Glebar’s P4K gauging system was designed

Medical Bone Drill | GT-610 CNC

Challenge: Infeed grinding 0.010” on two diameters over a 7” long metal drill blank in one operation while maintaining 0.0002” diameter accuracy, .00006 roundness and maintaining part straightness and concentricity. Solution

Medical Manufacturing Technologies (MMT) Enhances Abrasive Technology and Microblasting Capabilities with Strategic Acquisition of Comco

MMT announces the acquisition of Comco, a recognized leader in the micro-precision sandblasting sector, to enhance MMT’s abrasive technology offerings and microblasting capabilities.

Medical Manufacturing Technologies Enhances Product Line with Acquisition of FEPeeler, Unveiling Advanced Heat Shrink Removal and Braided Catheter Cutting Solutions

CHARLOTTE, NC and MINNEAPOLIS, MN – April 14, 2025 – Medical Manufacturing Technologies (MMT), a portfolio company of Arcline Investment Management and a leading global provider of medical device manufacturing

Medical Precision Cutting Tool Manufacturing

With over 20 years of cutter development and hole-making expertise, MMT’s applications team delivers advanced solutions in medical precision cutting tool manufacturing. We’re here to equip your team to meet

Menghini

Challenge Converted OD grinders with custom tooling and soft grinding wheels all of which wear at a high rate. Setup and changeover time is significant and requires extensive mechanical adjustments.

Micro Centerless Grinding & Burr-Free Electrochemical Cut Off

Micro Centerless Grinding Solutions LEARN MORE Applications Library LEARN MORE Burr-Free ECG Cutoff Solutions LEARN MORE

Micro Grinding: CAM2

The Glebar CAM.2 Micro Grinder is the perfect machine for grinding small, complex, precision medical applications such as complex medical guidewires, radiuses, needle points, and non-linear shapes. Previously unproduceable parts

MMT Acquires Innova

MMT announces the acquisition of Comco, a recognized leader in the micro-precision sandblasting sector, to enhance MMT’s abrasive technology offerings and microblasting capabilities.

MMT Unveils the Glebar P5K Gauging System: Revolutionizing Guidewire Measurement and Metrology Processes with Unmatched Speed and Accuracy

MMT announces the acquisition of Comco, a recognized leader in the micro-precision sandblasting sector, to enhance MMT’s abrasive technology offerings and microblasting capabilities.

Multi Lumen Tubing

Multi-lumen tubes are extrusions that contain multiple channels, or passages, through the length of the tubing. This enables a larger capacity for varying devices in a smaller diameter tubing component.