Grinding Technologies

Precision Centerless and Electrochemical Grinding Technologies

Achieve high-volume production without sacrificing precision. Our precision grinding technologies combine compact design with powerful performance, making them ideal for manufacturers who require speed, accuracy, and reliability in every cycle. Built for demanding applications, our space-saving electrochemical (ECG) and centerless grinding machines are engineered to reduce costs and maintain the tight tolerances today’s medical, automotive, aerospace, defense, and general industrial applications require.

From guidewires and Nitinol tubing to ceramic shafts, carbide rods, fasteners, and beyond, our grinding technologies support a wide range of components from a variety of industries. Whether you're scaling production or refining a complex process, we deliver tailored, turnkey systems designed to meet your exact specifications.

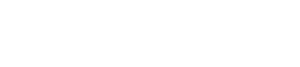

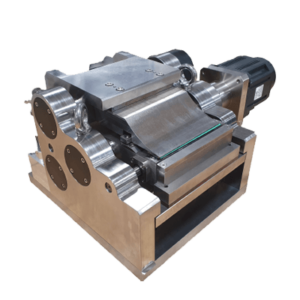

TF-9DHD Infeed/Throughfeed Centerless Grinder

The TF-9DHD Infeed/Throughfeed Centerless Grinder uses computer controls to grind both hard and soft materials including catheters, medical guidewires, and spinal cord stimulators. Inside the compact footprint is a 15HP main spindle motor powering an 8.625” wide work wheel combining to remove more material faster, and with better surface finishes, than similar machines with narrower grinding wheels. The TF-9DHD is designed to enhance productivity through a simple control interface and automation integration.

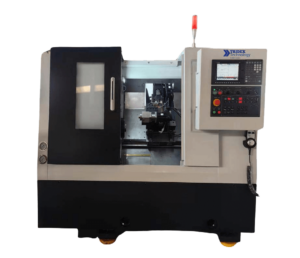

CAM.2 Micro Grinder

The CAM.2 Micro Grinder can produce flats, radiuses, needle points, and non-linear shapes; the perfect machine to grind complex medical guidewires, dental parts, and small precision parts for various industries. Combining the latest in multi-axis servo motor control, submicron positioning, and an intuitive 15″ HMI, the CAM.2 offers unmatched performance. With the CAM.2’s full-fledged G-code underpinnings, direct integration with CAD/CAM packages is seamless. Previously unproduceable parts can be made easily, with minimal setup time, and with limited operator training.

GT-610 Centerless Grinders

The Glebar modular GT-610 Series of precision Infeed/Thru-feed Centerless Grinders remove more material faster, and with better surface finishes than competing machines. Applications for machines within this series include aerospace fasteners, automotive transmission components, engine parts, and valve stems, PCD drill bits, arthroscopic bone shavers, bone drill blanks, medical device components, and more.

Search By

Technologies

or Brand.

Applications | Technologies

Brands

Diamond Point

Challenge Converted OD grinders with custom tooling and soft grinding wheels all of which wear at a high rate. Setup and changeover time is significant and requires extensive mechanical adjustments.

DM-12 CNC Grinding Wheel Dressing Machine

New Product! The Tridex DM-12 CNC Grinding Wheel Dressing Machine is your standalone solution for precision grinding wheel dressing. Capable of dressing wheels up to 12” (310mm) in diameter and

Double Deck Laminator

Laminate multiple catheter shafts simultaneously. https://www.youtube.com/watch?v=3mPM3siYRzQKey Features Automated Core Wire Stretching post-lamination to facilitate easy removal of Core Wire Catheter Shaft tooling automatically moves towards the operator to provide for

Drug Eluding Stent Crimping: CRF-200-PS

https://www.youtube.com/watch?v=fBfxlEWwKfA The CRF-200-PS is a stable stent crimping system with film protection for the processing of drug-eluting self-expandable stents. Fully enclose drug residue with our unique 4-film protection system combined with the

Dual Feeding: Accu Feed DFS

The Dual-Feed system consists of two feeding processes mounted onto a high-quality, aluminum extruded, anodized rotary stand. This catheter manufacturing tube feeding machine provides precise alignment for variable cutting production.

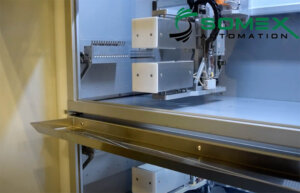

ECG Slot Grinding of Castle Nuts Eliminates Need for Secondary Operations | SG-1645

Castle Nuts, also referred to as Castellated Nuts, are used for applications in aerospace and automotive markets where the nut cannot loosen. A cotter pin or safety wire is inserted through a cross-drilled bolt

Electrochemical Cutting and Grinding Provides Faster Cuts and Greater Accuracy Than Laser Cutting | CS1-E

Current Process A high-powered laser beam cuts the tubing by melting it leaving a rough edge and slag. Tubes and other parts are typically cut one at a time limiting

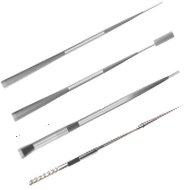

Electrochemical Grinding Allows for Bulk, Burr-Free Point Grinding of Orthopedic Wires and Pins | PGS-100

Challenges -Grinding Kirschner wires, or K-wires, using a manual OD grinder poses challenges that directly impact production efficiency. -The slow output of grinding one wire at a time, lengthy changeovers

Electrochemical Grinding: Point Grinding PGS-100

The Tridex PGS-100 Burr-Free Electrochemical Point Grinding System is a fully programmable pointing and material handling system that easily integrates with the Tridex SG-1645 or SG-2060 ECG Grinders. Using ECG,

Electrochemical Grinding: SG-1645

The Tridex SG-1645 Burr-Free Electrochemical NC/CNC Surface Grinder is a faster alternative to traditional surface grinding. By providing burr-free and low-force grinds that leave no heat-affected zones it virtually eliminates

Electrochemical Grinding: SG-2060

The Tridex SG-2060 Burr-Free Electrochemical CNC Surface Grinder is a faster alternative to traditional surface grinding. By providing burr-free and low force grinds that leave no heat-affected zones it virtually

Elongated Shaft Hole-Drilling & Skiving

Unique applications may require unique solutions. Lean on our 25+ years of catheter manufacturing expertise to help engineer repeatable solutions and improve product quality, rate of production, & supplementary services.

Endotracheal Tube Tipping

Does increased production sound interesting? In addition to flashless tipping, clean hole-drilling & higher yield of quality parts, we offer extensive customization of our tooling platform to meet your production

Enhanced Throughput and Pinpoint Precision Elevate Form Grinding on Glebar’s New PG-912DG Enclosed Centerless Form Grinder

Glebar’s Applications Division conducts research and development of innovative cutoff and grinding technology. Their most recent focus was to innovate the existing design of our PG-9 series of Centerless Plunge

Extrusion Die Stretcher

The Extrusion Die Stretching Machine (figure 1) performs hot die draw-down of plastic tubing used in catheter production. Three different models are available, 3×26, 3×68, and 3×80, letting you maximize

Felt Tips | PG-9BHD

Challenge: To grind felt tips for pens. Customer required a high volume turnkey solution. Solution Before finding Glebar, the customer was grinding these felt tips manually. Glebar sold the customer a

Filler Spouts | GT-610

Challenge: A food equipment manufacturer approached Glebar to improve productivity and reduce costs for their food filler machines. The metal spout requires grinding for several reasons. They come in contact with

Flex-Drill Power Feed

We are available to assist you with your projects from proof-of-concept to production. We continue to hear from you and innovation and acquisition are one result. We’d like to welcome

Flexible Stent Crimping: CR-240 FSCP

The CR-240-FSCP Flexible Stent Crimping Platform is developed for the crimping and transfer on or into the delivery system. Both balloon expandable and self- expandable stents up to 220 mm

Form Grinding Ball Valves In-House Improves Output, Reducing Production Time and Saving Costs | PG-9DHD

Current Process: The balls are formed one at a time from bar stock on a lathe in multiple roughing and finishing tool paths. Molded balls are purchased from a contract

Form Grinding of Deodorant Balls | PG-9BHD

Challenge Manufacturers use lapping machines which are unable to hold consistent tolerances or capacity, creating inconsistent surface finishes and longer cycle times. Provide a form grinding solution for 1″ and

Full Radius Tipping & Multi-Hole-Drilling

SPOTLIGHT ON: Integrated Tipping and Hole Drilling Solutions Power: CATHTIP RF tipping generators can generate enough heat to form the largest catheter tubes you need. Control: Experience the tightest resolution of heat

FW-9D: OD Grinder

The FW-9D offers a unique version of plunge grinding where the outside shape (OD) of the product is ground relative to the center of the part. This unique technique solves

Gas Pressure Leak Tester: GPL-501 B

The Interface gas pressure leak tester, model GPL-501, is a tabletop machine used for nondestructive leak testing of catheter components using dry nitrogen gas. Nitrogen gas is inert so there

Gas Pressure Leak Tester: GPL-5020

The Interface Gas Pressure Leak Tester, Model GPL-5020, is designed for rapid, non-destructive testing of catheters. Its modular construction allows for expanding the number of test ports from one to

GFS: Automatic Wire and Tube Feeding System

https://vimeo.com/269650845 The Glebar GFS is a stand-alone device which can seamlessly connect and feed parts into existing third-party machines including swiss screw machines, manual grinding machines, and more. The control

Glass Rods | PG-9X20DHD

A top tier technical glass OEM required a precision grinding solution for quartz glass rod components which will be transformed into fiber optic cable cores. They needed to improve their

Glebar Customer Care Provides Training and Support, Returning Focus to Making Parts

Current Process & Challenges: Self-Performing Maintenance and Service Increasingly Costly In the past, it was cost and time-efficient for manufactures to retain maintenance, training, and supply chain management in-house. However,

Golf Ball Cores | PG-9DHD

Challenge: To mass produce golf ball cores at a low cost, while holding tight tolerances with maximum throughput. Solution Glebar designs and builds networked machines with the ability to gather production

Guidewire Deburring Machine

The Glebar GSR-6 Guidewire Deburring Machine deburrs guidewires while automatically separating pass and fail parts and counting the number of wires processed. This automated process removes the operator, avoiding repetitive

Guidewire Feeding: Accu Feed 410 & 510

The 410 & 510 guidewire centerless grinder feeders handle wire for manufacturing processes such as guidewire centerless grinding, tip forming, bead blasting, or cleaning. The medical guidewire feeding machines are configurable

Guidewire Feeding: Accu Feed AGF

The Advanced Guidewire Feeder is the optimal wire feeding solution for centerless grinding processes. It improves production speed, accuracy, and quality while delivering a substantial return-on-investment. This medical centerless guidewire

Guidewire Grinder: GT-9AC

The Glebar GT-9AC Automated Guidewire Grinder excels at precision grinding of medical guidewires with multiple tapers, paddles, and parabolic shapes with speeds as fast as a centerless grinder. Instead of

Guidewire Jacketing System: Accu Feed GJS

The Guidewire Jacketing System automates the singulation, feeding, coating, inspection, and binning process around 3rd party extrusion systems. The machine features variable, programmable pulling speed capability that allows for high-resolution

Guidewires (Cycle Time Reduction | CAM.2)

Challenge: Cycle time reduction and a sharp corner needed for a medical guidewire Solution The CAM.2 machine has several modes of operation configurable for different shaped guidewire geometries. In this case,

Guidewires (Gauging | P4K)

Challenge: Lack of a clear, simple method to inspect the geometric profile of many components. Existing systems are slow, unreliable, and complex to operate. Solution Glebar’s P4K gauging system was designed

Guidewires (Process Efficiency | CAM.2)

Challenge: To eliminate additional processes in the production of guidewires. The conventional process uses several machines to profile a shape in an interventional guidewire. Solution Glebar eliminated pre- and post- processes

Guidewires (Rapid Changeover | GT-9AC)

Challenge: A Medical device customer needed to rapidly changeover between a family of Nitinol guidewires having various lengths and geometries. Since the geometry of the components varied in length, the customer

Heat Setting Oven

Heat setting wrapped balloons at too high a temperature, such as those used for balloon forming, can lead to shrinkage and changes in mechanical properties. Heat setting at lower temperatures

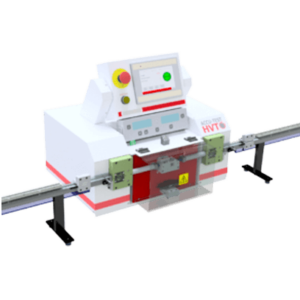

High Voltage Test System: Accu-Test HVT

The High Voltage Spark Tester (HVT) provides fast, accurate detection of metal-reinforced catheter shafts or coated guidewires. The catheter shaft detection machine features a wide product test range, optional automatic feeding and