Precision Technologies Portfolio

Search By

Technologies

or Brand.

Applications | Technologies

Brands

Carbide Rods (Tungsten) | PG-9X20DHD

To establish a process whereby pre-sintered carbide drill blanks processed in a hot isostatic press (HIP) can be pre-sized to produce straight rod stock for long blanks. The existing method

Catheter Bodies | TF-9DHD

Challenge: To point and shape catheter bodies free of debris and scratches, at high production rates. Solution Some catheters require a grinding operation after extrusion in order to taper the distal

Catheter Component Processing

At MMT, we are proud to offer top-notch services and support for catheter and guidewire manufacturing. Our services cater to a diverse range of OEMs and contract manufacturers. Whether you

Catheter Cost Solutions

This month we’re serving up options. Options for how to keep YOUR projects moving forward in this atypical business climate. Because CATHTIP is fully-integrated we can offer you solutions to

Catheter Drilling and Cutting System

SYNEO’s Automated Catheter Drill and Cut systems allow engineers to produce finished, drilled and precision cut-to-length catheter components in a continuous and fully automated manufacturing process. Raw materials can be presented

Catheter Laminating Reflow Machine

Cath-Tech (CT) Reflow Chamber The Cath-Tech (CT) Reflow Chamber is a precision catheter laminating machine designed for consistent, high-quality results. It uses a tightly controlled heated chamber that moves along

Catheter Laminating: 311

EBD Quad Catheter Laminator shrinks catheter tubing faster than the competition. Designed for vertical operation, its patented hot air circulation process contains the heat within the system, maximizing the time

Catheter Laminating: Reflow Clam Shell

The CT Reflow Clam machine differs from the CT Reflow Chamber machine because of its ability to be programmed to skip over various parts of a catheter assembly, therefore removing

Catheter Laminating: Reflow Roller

The R&D Engineering Reflow Roller boasts eight (8) chambers that continuously feed the product, and enable a quick transition between loads by the operator. This easy-to-control, compact machine is not

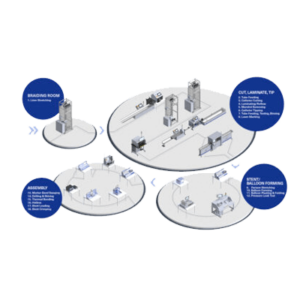

Catheter Manufacturing Process

1 Liner Stretching 2 Tube Feeding 3 Catheter Cutting 4 Laminating/Reflow 5 Mandrel Removing 6 Catheter Tipping 7 Tube Feeding, Testing, Binning 8 Laser Marking 9 Parison Stretching 10 Balloon

Catheter Production Fixtures

Figure 1: Balloon Trimmer/Tip Cutter Performs precision square end cuts to specified lengths. Quick and repeatable results on items such as balloon necks and catheter tips. Figure 2: Slitting

Catheter Skiving Slotting Video

Let us introduce you to something new for your R&D or clean room repertoire: the CATHTIP Skive Capsule (patent pending). Slotting or skiving your catheter tubing just got easier.

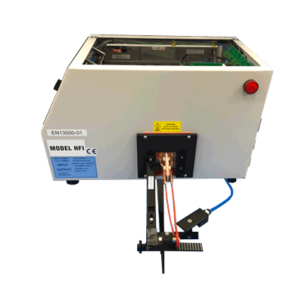

Catheter Tipping and Hole Forming Machines

MMT develops catheter tipping and hole forming equipment and technology solutions that support complex medical device manufacturing with precision, speed, and reliability. Our team brings together application-specific knowledge, in-house tooling,

Catheter Tipping Characterization Process

We hope you and your families are holding up well at this time. CATHTIP continues to provide needed equipment and services to our valued customers. Some of you are turning

Catheter Tipping: Magnum

The Magnum provides the most flexible RF architecture on the market, capable of tip forming, flaring, and bonding in R&D or production settings. Our state-of-the-art, precision catheter forming systems produce

Catheter Tipping: Nexus RF Tipper

New Product! The Cathtip Nexus is the perfect combination of power and convenience. Boasting an impressive 1.2kW of power, this machine sets the standard for compact desktop-sized catheter tipping machines.

Catheter Tipping: Quantum

The Quantum is a tabletop tipping machine designed to produce superior outputs expected of the CATHTIP standard. Our state-of-the-art, precision catheter forming systems produce the highest quality parts with speed

Catheter Tipping: R&D Radio Frequency

Our Radio Frequency Tipping Machine uses RF energy which improves application processing speed as it automatically starts at the desired temperature. Additionally, it provides more flexibility to the dies when

CATHTIP Equipment Add-Ons

We love helping our customers! From flashless catheter tipping, to burr-free hole forming, our equipment produces the consistent, quality parts you need. Whether your project is manufactured in your cleanroom

CATHTIP now a sister company to SYNEO Company

Happy Thanksgiving! We are thankful for you our loyal customers! This has been a unique year, to say the least, and we want to take a moment to express our

Center Pick feeding: Accu Feed CPF

The SYNEO branded Center Pick Feeder targets similar applications as its well known counterpart the 110 Feeder but with a significantly smaller floor space requirement. This compact medical stick tubing

Centerless Form Grinder: PG-912 DG

The PG-912DG Enclosed Centerless Form Grinder uses a 12″ wide work wheel and servo motors to reduce setup times, increase throughput, and maintain tighter tolerances. The enclosed design features a

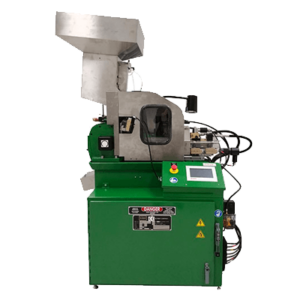

Centerless Form Grinder: PG-9BHD

The Glebar PG-9BHD Centerless Form Grinder produces spherical or cylindrical components from pre-form or rod in a range of materials, including rubber, ceramics, wood, plastic, glass, and Teflon® (PTFE). Starting

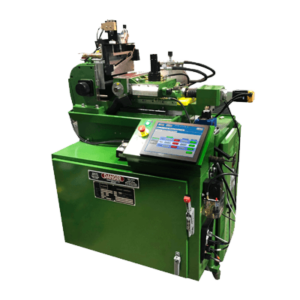

Centerless Form Grinder: PG-9DHD

The Glebar PG-9DHD Centerless Form Grinder is a high-precision version of the Glebar PG-9BHD. With its 10″ wheel, this form grinder is capable of multiple-part-per-cycle grinding, also offering precise slide

Ceramic Insulator Bodies | FW-9D

Challenge: To grind a ceramic insulator body for lean burn gas engines for use in cogeneration plants and containerized power generation units. Customer required four diameters as well multiple compound angles

Closed Loop Control on your Magnum

SPOTLIGHT ON: Closed Loop Feedback & Control for Tube-Forming CATHTIP Magnum RF tipping machines can utilize any of the built-in closed loop control features for force, temperature, or current –

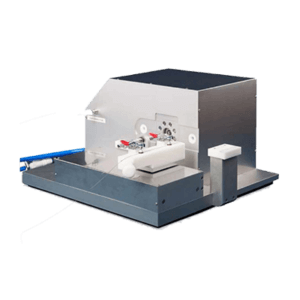

CNC Wheel Dressing Machine: DM-9CNC

The Glebar DM-9CNC is a standalone dressing machine designed to dress 9″ (229mm) diameter by up to 10-1/8″ (257mm) wide wheels used on the PG-9BHD and PG-9DHD Plunge Grinders. It

Coil Winder: 503 Single Filar

EBD Coil winding technology is developed specifically to wind micro coils for minimally invasive medical devices. Delivers the ability to wind coils using filament as small as .001″ diameter on

Composite Strips | DD-7

Challenge: To grind both sides of composite strips (fiberglass), fully automated at high speed with tight tolerances. Solution Using Glebar’s DD-7 Double Disc Grinder (one of the smallest on the market),

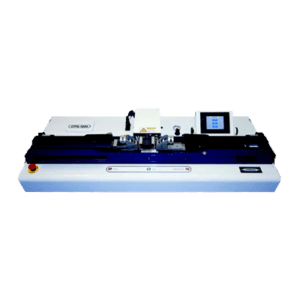

CPS 1000 – Computerized Parison Stretcher

The Interface branded parison stretcher, CPS-1000, is a system designed to stretch or neck-down tubing parisons in preparation for the balloon forming process. It is easily programmable through the tilt

CR-60-HC Bioabsorbable Stent Crimping Machine

The MPT CR-60-HC Stent Crimping Machine is developed for the crimping of balloon expandable bio absorbable stents. Key Features Stent and balloon positioning outside of crimper head. Crimp head can

CS1-EA: Hybrid Burr-Free and Precision Abrasive Cutoff Machine

The Tridex CS1-EA Hybrid Burr-Free Electrochemical (ECG) & Precision Abrasive Cutoff Machine combines the best of the CS1-A Precision Abrasive and CS1-E Electrochemical Cutoff machines into one robust and compact

Custom Razor Blades for Skiving

Custom razor blades for skiving offer significant advantages in scenarios requiring precise and specialized cutting needs. By offering a tailored solution, MMT’s FEPeeler Custom Razor Blades enhance the quality and

Cutting Multiple Steel Bars with Precision Abrasive Cutoff Machine Reduces Production Time for Aerospace Fastener Manufacturers | CS1-A

Current Process Conventional cutting processes use an abrasive chop saw, band saw, lathe cutoff, or shear cutting machine. Each method has its disadvantages. Tooling wears quickly and is expensive, driving

DD-7: Double Disk Grinder

The Glebar DD-7 Double Disk Grinder has the smallest footprint of any double disk grinder on the market. It is designed for grinding small components, accurately controlling their length and

Dereeler: Accu Feed HPD

The Accu-Feed HPD High Performance Dereeler is similar to the Accu-Feed LTD in design and function. However, the HPD can handle a much larger spool as well as heavy gauge

Dereeler: Accu Feed LTD

The Accu-Feed LTD Low Tension Dereeler is designed to provide constant strain, low tension payout of tubing to an Accu-Cut or other machine for high volume, critical tolerance manufacturing operations.

Device Assembly Services

At MMT we offer a host of medical manufacturing services, including device assembly services. As experts in the medical device manufacturing industry, we hold a competitive advantage with catheter component

Diameter Measurement Systems

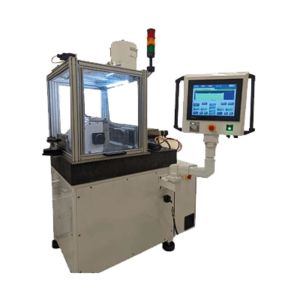

Designed specifically for catheter balloons, the Interface Catheter Solutions Length Diameter Measurement System, LDS-320 offers an accurate, non-contact, low-cost technique for catheter balloon dimensional inspection. It eliminates errors associated with

Diamond Point

Challenge Converted OD grinders with custom tooling and soft grinding wheels all of which wear at a high rate. Setup and changeover time is significant and requires extensive mechanical adjustments.